Working on a jig to weld an aluminum sheet metal part. Goal is to keep flatness tight and hold final dimensions during and after weld. I’ve roughed up a first draft of the fixture – but wanted to throw it out to the hive mind here to see how others would approach it. Would love to hear how you'd jig this up.

Here’s what’s up:

The part is aluminum, not too thick, mostly flat geometry.

Tolerance on flatness is critical post-weld.

I can split the part however – no restrictions on where seams go.

Jig needs to handle minor distortion from weld heat – or at least contain it.

Attached are:

Model of the part

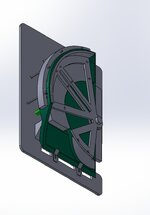

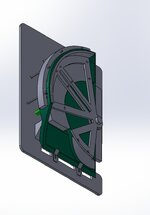

First jig concept I built

If you were me, how would you jig this up? Any pro tips on controlling distortion with aluminum specifically? Appreciate all input – trying to make this tight.

Here’s what’s up:

The part is aluminum, not too thick, mostly flat geometry.

Tolerance on flatness is critical post-weld.

I can split the part however – no restrictions on where seams go.

Jig needs to handle minor distortion from weld heat – or at least contain it.

Attached are:

Model of the part

First jig concept I built

If you were me, how would you jig this up? Any pro tips on controlling distortion with aluminum specifically? Appreciate all input – trying to make this tight.