I work in a manufacturing facility and we're mounting a robot to a semi-moveable skid so it can be moved as needed. The goal being that the robot can be moved & reconfigured to do different tasks as needed without needing to rip up concrete, etc. The skid is pretty straightforward, C channel wrap around with plate steel welded on top & fork pockets to handle movement. Robot and controller station is bolted to the plate steel.

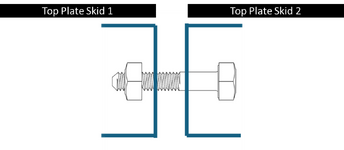

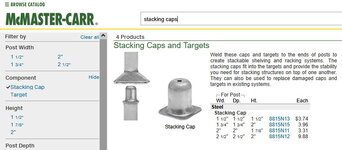

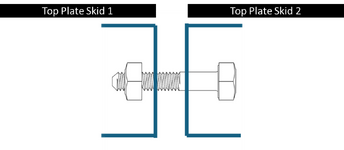

We need to build a second skid for part storage. This skid will consist of a loading table, basic mechanism, etc. I'd like to bolt these skids together for stability purposes to ensure the system stays together during operation. For movement; I'd unbolt the skids and move them independently in order to fit through doorways. (I'm not worried about maintaining system 0 during movement.) I can't think of a way to bolt the skids together to make a smooth work platform without building a skid that requires you to bolt it together underneath the top plate. From a maintenance/assembly practice; that's annoying because I no longer have bolt access. I refuse to believe that I'm the first one to decide to bolt two skids together with the option to semi-conveniently unbolt them. What solutions am I missing?

We need to build a second skid for part storage. This skid will consist of a loading table, basic mechanism, etc. I'd like to bolt these skids together for stability purposes to ensure the system stays together during operation. For movement; I'd unbolt the skids and move them independently in order to fit through doorways. (I'm not worried about maintaining system 0 during movement.) I can't think of a way to bolt the skids together to make a smooth work platform without building a skid that requires you to bolt it together underneath the top plate. From a maintenance/assembly practice; that's annoying because I no longer have bolt access. I refuse to believe that I'm the first one to decide to bolt two skids together with the option to semi-conveniently unbolt them. What solutions am I missing?