A question for those interested in composite panel buckling.

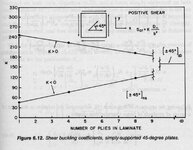

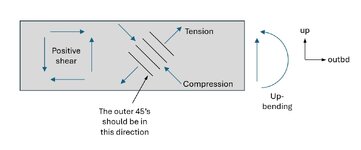

It has been a curiosity as to why edge shear on a typical panel or structure is generally treated as a positive value or magnitude. It seems to be a practice and for metallics, it would be reasonable to assume that as metal is more a less isotropic, then behaviour is reversible. However, a panel subject to diagonal tension across one diagonal caused by shear alone, then reverse the shear direction (e.g. a wing in twist reversal), the buckling mode can differ and the buckling and post buckling capability can be quite different. Sol 106 Buckling I think looks after all this I think in reality. But in the pencil days , it did not.

Add to this, composites as a material. The sensitivity to the direction of shear could be quite profound.

Recently while bench mark testing a new buckling and laminate strength analysis program, I was given the task of verifying the tools simulation results against physical tests conducted by NASA in the 60's as sort of bench mark studies, for balanced composites and unbalanced composites and single curvature panels. The tool did not accept the negative shear value to represent load reversal but the geometry of the test simulation could be reversed so the loads were for all effective purposes be reversed. The result were some what unexpected and might have implications for composites. It was possible to see major differences in behaviour in panel buckling capability especially for low ply numbers. Even some high ply layups up around 20 ply, ocassionally there were substantial differences.

There is a tendency when setting up the loads going into sol 106 to simply put in the magnitude of the shear and not the direction. Sol 106 will take negative shear.

Has anybody actually encountered practical implications from this simplification of shear direction and buckling.

It has been a curiosity as to why edge shear on a typical panel or structure is generally treated as a positive value or magnitude. It seems to be a practice and for metallics, it would be reasonable to assume that as metal is more a less isotropic, then behaviour is reversible. However, a panel subject to diagonal tension across one diagonal caused by shear alone, then reverse the shear direction (e.g. a wing in twist reversal), the buckling mode can differ and the buckling and post buckling capability can be quite different. Sol 106 Buckling I think looks after all this I think in reality. But in the pencil days , it did not.

Add to this, composites as a material. The sensitivity to the direction of shear could be quite profound.

Recently while bench mark testing a new buckling and laminate strength analysis program, I was given the task of verifying the tools simulation results against physical tests conducted by NASA in the 60's as sort of bench mark studies, for balanced composites and unbalanced composites and single curvature panels. The tool did not accept the negative shear value to represent load reversal but the geometry of the test simulation could be reversed so the loads were for all effective purposes be reversed. The result were some what unexpected and might have implications for composites. It was possible to see major differences in behaviour in panel buckling capability especially for low ply numbers. Even some high ply layups up around 20 ply, ocassionally there were substantial differences.

There is a tendency when setting up the loads going into sol 106 to simply put in the magnitude of the shear and not the direction. Sol 106 will take negative shear.

Has anybody actually encountered practical implications from this simplification of shear direction and buckling.