DurgaprasadM

Marine/Ocean

- Jul 7, 2025

- 2

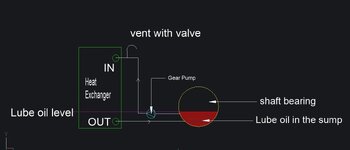

The lube oil present in the shaft bearing sump has to be cooled externally using a heat exchanger. A gear pump is being used to circulate the lube oil from sump to the heat exchanger. This is a closed system. During the initial startup, the vent valve will be used to purge all the air in the circuit. The moment gear pump is switched off, it is expected that there will be vacuum in the system above the lube oil level (Magenta line). During the next start up of gear pump, is there any problem with this vacuum? If yes, what is the solution.

Note: I cannot able to provide a header tank as there is restriction of lube oil level in the sump of shaft bearing.

Note: I cannot able to provide a header tank as there is restriction of lube oil level in the sump of shaft bearing.