Hello

I'm designing a stainless steel hinge with bronze bushings, and I've chosen to secure the pin using two E-type circlips.

I would like to know if the circlips can withstand the loads (which I don't know how to calculate).

I would like to create a calculation note to verify whether my design solution is suitable.

Could you help me, please?

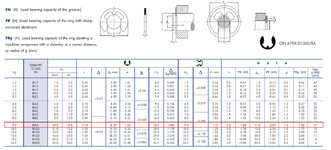

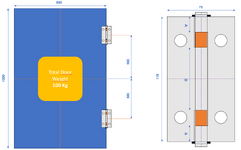

Here are the conditions.

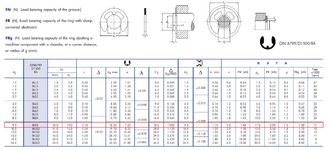

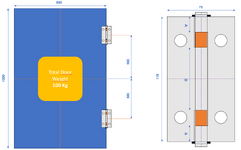

Here are the allowable forces specified by the circlip manufacturer.

I'm designing a stainless steel hinge with bronze bushings, and I've chosen to secure the pin using two E-type circlips.

I would like to know if the circlips can withstand the loads (which I don't know how to calculate).

I would like to create a calculation note to verify whether my design solution is suitable.

Could you help me, please?

Here are the conditions.

Here are the allowable forces specified by the circlip manufacturer.