NotHandyRandy

Computer

- Nov 5, 2024

- 5

Hello,

Mounting scissor lift

Hi everyone,

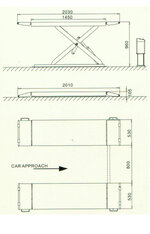

I recently acquired a mid-rise scissor car lift rated for 9,000 lbs, and I'm planning to use it for vehicles up to a maximum of 5,500 lbs. Here's a photo of the lift:

lift dimensions: https://i.ibb.co/CsVGv8QB/IMG-7145.jpg

lift dimensions: https://i.ibb.co/CsVGv8QB/IMG-7145.jpg

Unfortunately, the manufacturer is out of business and there are no official specs or installation guides available.

### Lift Details:

* **Lift Type:** Mid-rise scissor

* **Capacity:** 9,000 lbs - I will do max 5500 lbs

* **Platform Size:** 22” wide x 54” long (each side)

* **Mounting Surface:** Residential garage

* **Concrete Slab Thickness:** is 4" (measured two test holes; for safety at 4 1/2”+ I’m conservatively assuming 4”)

### My Plan:

I'm considering anchoring the lift with **epoxy-set anchors**. I'd prefer to use **5/8” anchors**, but most manufacturers data sheets specify **1/2”** epoxy anchors for 4” slabs.

Interestingly, a U.S. company that sells a

mid-rise 2-post lift allows installation on 4” concrete and includes **5/8” sleeve anchors** — though I’m unsure if sleeves are ideal in this application I could buy those. Brand is Max Jack, two post stresses concrete a lot more no ?

### What I Need Help With:

* Is it reasonable/safe to use 5/8” **epoxy anchors** in a 4” slab?

* Are **sleeve anchors** advisable in this context, or would **epoxy or wedge anchors** be better?

* General advice or best practices you’d follow in this situation?

Thanks in advance for any insights. I know no one here can assume liability, but I’d appreciate experienced suggestions to help me approach this as safely as possible.

Thank you

Mounting scissor lift

Hi everyone,

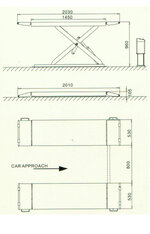

I recently acquired a mid-rise scissor car lift rated for 9,000 lbs, and I'm planning to use it for vehicles up to a maximum of 5,500 lbs. Here's a photo of the lift:

Unfortunately, the manufacturer is out of business and there are no official specs or installation guides available.

### Lift Details:

* **Lift Type:** Mid-rise scissor

* **Capacity:** 9,000 lbs - I will do max 5500 lbs

* **Platform Size:** 22” wide x 54” long (each side)

* **Mounting Surface:** Residential garage

* **Concrete Slab Thickness:** is 4" (measured two test holes; for safety at 4 1/2”+ I’m conservatively assuming 4”)

### My Plan:

I'm considering anchoring the lift with **epoxy-set anchors**. I'd prefer to use **5/8” anchors**, but most manufacturers data sheets specify **1/2”** epoxy anchors for 4” slabs.

Interestingly, a U.S. company that sells a

mid-rise 2-post lift allows installation on 4” concrete and includes **5/8” sleeve anchors** — though I’m unsure if sleeves are ideal in this application I could buy those. Brand is Max Jack, two post stresses concrete a lot more no ?

### What I Need Help With:

* Is it reasonable/safe to use 5/8” **epoxy anchors** in a 4” slab?

* Are **sleeve anchors** advisable in this context, or would **epoxy or wedge anchors** be better?

* General advice or best practices you’d follow in this situation?

Thanks in advance for any insights. I know no one here can assume liability, but I’d appreciate experienced suggestions to help me approach this as safely as possible.

Thank you