Hi,

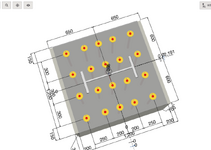

I am designing a base plate. The shear force is around 2200 kn. I am unable to use the anchor configuration given in EN 1992-4. I want to use some other configuration. my question - can we use supplementary reinforcements to prevent the breakout failure as per the code if we go with some other configuration? I am using HILTI profis. As soon as my configuration is changed from the standard the software does not show the option for supplementary rebars.

I am designing a base plate. The shear force is around 2200 kn. I am unable to use the anchor configuration given in EN 1992-4. I want to use some other configuration. my question - can we use supplementary reinforcements to prevent the breakout failure as per the code if we go with some other configuration? I am using HILTI profis. As soon as my configuration is changed from the standard the software does not show the option for supplementary rebars.