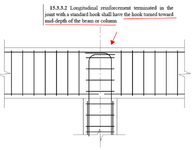

ACI 318-19 Section 15.3.3.2 requires column vertical bar hooks to be turned into the center of the column at the top of the column. In my opinion, turning the hooks inward into the column poses some problems, versus orienting them outward. The hooked bars would be easier to install if the hooks were turned outward. They would not be crashing into one another (especially if the hooks were on bigger vertical bars turning inward into smaller columns). The sketch shows #9 hooked bars turning into a 24"x24" column. Turning the hooks outward would also allow installation of the uppermost column ties to be installed immediately under the corners of the hooked bars (to facilitate development of those hooked vertical bars). I am just now reading through ACI 318-19. I don't think this requirement was in ACI 318-08 (the last version of ACI 318 that I was completely familiar with). What does turning the hooks into the column do that makes this "constructability challenged" hook orientation so important? Does anyone know what precipitated this change? Also, a number of other "top of column" details in various ACI publications show the hooks oriented outwards!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations JStephen on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ACI 318-19 Section 15.3.3.2 column vert bar hooks

- Thread starter cliff234

- Start date

HTURKAK

Structural

- Jul 22, 2017

- 3,406

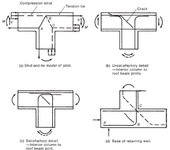

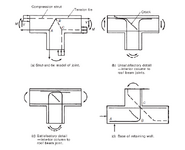

The latest detail at acı 318-19 is better than the previous ones . Unluckily ACI 318 is silent for the reason and does not give specific guide lines for the design of joints. You can draw a STM model and see that the latest detail is more effective. The following figure is copy and paste from REINFORCED CONCRETE ( By James Kwight )

I will suggest you to look ACI 352 R and the Detailing of concrete structures ( By Jörg Schlaich , in GERMAN ).

I will suggest you to look ACI 352 R and the Detailing of concrete structures ( By Jörg Schlaich , in GERMAN ).

- Thread starter

- #3

Thank you HTURKAK for your response! I’ll get a copy of the latest ACI 352. I still don’t see how turning the hooks into the joint will mitigate cracks, unless the hooks are made longer. I always had the mindset that the sole purpose of hooked bars was to facilitate the development of bars in tension. (The only time I use hooks longer than "standard 90-degree hooks" is on bars in cantilevered retaining wall footings as shown in detail (d).) Detail (b) (hooks turned outward) is labeled “unsatisfactory”. Detail (c) is labeled “satisfactory”. Interestingly, the hooks in detail (c) are graphically shown longer, but no other dimensional information is provided. Wouldn’t an alternative (and possibly improved) solution be to extend the column ties into the slab/beam/footing. In my opinion, the diagonal tension cracks shown in the illustrations would be better restrained by ties. Also, there are already continuous longitudinal bars parallel to the hooked bars – so why the need to turn the hooks inward if there is already reinforcing steel to restrain the cracks?

Attachments

HTURKAK

Structural

- Jul 22, 2017

- 3,406

Good point. The hooks shall be reasonable long enough to develop full joint resistance. Consider the forces at picture (a), the shear forceI still don’t see how turning the hooks into the joint will mitigate cracks, unless the hooks are made longer.

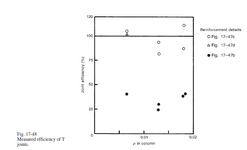

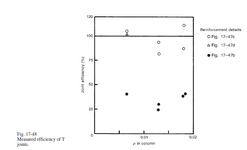

in the joint increase the diagonal cracks, so requires column stirrups to be continuous in the joint . The detailing of longitudinal reinforcement also substantially affects the efficiency of the joint. Have a look 2nd picture . While efficiency of joint detail ( b) was in the range of only 25–45 % , the efficiency of joint detail ( c ) where the bars are anchored in the joint core , was in the range of 85–110 % .

I asked about something similar before:

www.eng-tips.com

www.eng-tips.com

Retaining Wall Base Crack Pattern - Structural engineering general discussion

Hi Everyone, I have some questions regarding this previous discussion: https://www.eng-tips.com/viewthread.cfm?qid=401855. Navigating the various references in the post, I tried to understand the crack pattern at the intersection between the retaining wall and the footing. Using plane stress...

The detail was changed to create a condition whereby the beam to column connection would serve as a better detailed moment connection. We looked at a similar situation ad nauseum the thread below. It's basically the fundamental rebar detailing principle that hooks should face the struts that they are meant to restrain.

I also prefer hooks out even if hooks in is a better detail in a mechanical sense. I'll take weaker detailing over congested, low quality concrete most days of the week.

https://www.eng-tips.com/threads/re...-stem-into-footing.401855/page-8#post-8186764

I also prefer hooks out even if hooks in is a better detail in a mechanical sense. I'll take weaker detailing over congested, low quality concrete most days of the week.

https://www.eng-tips.com/threads/re...-stem-into-footing.401855/page-8#post-8186764

- Thread starter

- #7

I also prefer hooks out even if hooks in is a better detail in a mechanical sense. I'll take weaker detailing over congested, low quality concrete.....

I agree!

- Thread starter

- #8

Thank you for your responses KootK, HTURKAK, and Nick6781! In my opinion ACI 318-19 Chapter 15 does not explain the requirements for beam-to-column moment connections (and the required details) clearly enough to be of any use. I am still a bit confused. The fact that the hooks need to be extended is not mentioned (and how far do they need to extend?). And I'm wondering why the hooks would even have to be extended if there is continuous top reinforcing already running over top of the joint each way. I think I'm going to leave the hooks pointing outward (as has been standard practice for the last 50 years), and make sure that I always have several continuous top bars each way over all columns for (among other reasons) diagonal crack control. I don't like the possibility of excessive rebar congestion occurring if the hooks are turned into the column - especially with smaller column sizes. I'm also going to extend the column ties to the top of the slab to restrain formation of diagonal cracks.

slickdeals

Structural

For what it's worth, it looks like 318-25 has reorganized Chapter 15 a bit more. As far as I can see, this requirement has been removed for slab-column joints.

- Thread starter

- #10

slickdeals: Thank you for that update! I guess it's time for me to order my copy of ACI 318-25.For what it's worth, it looks like 318-25 has reorganized Chapter 15 a bit more. As far as I can see, this requirement has been removed for slab-column joints.

OldDawgNewTricks

Structural

As slickdeals wrote, the requirement has been removed for slab-column joints in ACI 318-25. The requirement still remains for beam-column joints as shown in your OP sketch.

- Thread starter

- #12

Thank you OldDawgNewTricks for the clarification (and advance warning)!As slickdeals wrote, the requirement has been removed for slab-column joints in ACI 318-25. The requirement still remains for beam-column joints as shown in your OP sketch.

Lomarandil

Structural

This feels rational to me. KootK and Cliff's concern about concrete consolidation are going to be most pressing in shallow depth slabs. Beam column joints, while more congested, are also naturally going to get more attention for consolidationAs slickdeals wrote, the requirement has been removed for slab-column joints in ACI 318-25. The requirement still remains for beam-column joints as shown in your OP sketch.

- Thread starter

- #14

This (the rebar congestion at the column / roof slab joint) is not as bad as I thought. If you have an 8” flat plate roof slab sitting on a column, then the vertical bars exiting the top of the column (with hooks) can’t be larger than #5 bars – or else they won’t be able to develop within the slab. Therefore, regardless of what the vertical bars are in the top tier of the column, you’ll need to figure out how many #5 dowels you’ll need to transfer the unbalanced moment from the slab into the column and then lap splice those dowels with the column vertical bars. (This isn’t much different from what we need to do now. (example: You can’t have #9 column vertical bars hooking into an 8” roof slab.)

Similar threads

- Locked

- Question

- Replies

- 5

- Views

- 4K

- Replies

- 1

- Views

- 4K

- Replies

- 1

- Views

- 8K

- Question

- Replies

- 6

- Views

- 6K

- Locked

- Question

- Replies

- 20

- Views

- 10K