Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations TugboatEng on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

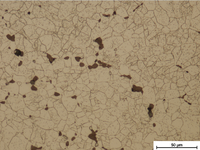

7050 Aluminum Alloy Microstructure

- Thread starter SMF1964

- Start date

mfgenggear

Aerospace

OP

There should be examples in the ASM heat treating hand book. Don't remember the upto date volume.

There should be examples in the ASM heat treating hand book. Don't remember the upto date volume.

mfgenggear

Aerospace

OP

Also AMS material specification for this material for castings and wrought material.

Also AMS material specification for this material for castings and wrought material.

- Thread starter

- #4

EdStainless

Materials

the current ASM handbook is two volumes newer than yours.

There also is an ASM specialty handbook on Al alloys that might help.

There also is an ASM specialty handbook on Al alloys that might help.

What was the material spec for the forged billet [block, etc]? What were the finished dimensions for the billet?

Was the forged billet HT processed to the -O1... or directly to the -T7452?

Did the billet have material certifications from the processor? IE...

What was the forging spec? Was billet grain size/control/flow checked? Chemistry/hardness/conductivity/tensile Checks?

Was a thru-ultra sonic required... in multiple orientations... and to what class was the block rated? Typical ASTM B594

Was this the billet a one-of-a-kind... or was-it-one of many in a lot 'heat'?

Has the impeller been 'in-service'?

/NOTE/ 7050 is a well-studied alloy with there are many technical papers many ... but know basic info on the raw-stock is a big starter.

I design lots of replacement parts from 7050 forged block and plate... raw stock certifications are the starting point.

If find the concept of an aluminum 'impeller'... with high rotation speed and fluid thrust... and likely vibrations and/or cavitation... a bit unnerving.

My head hurts... thinking too hard about this...

Was the forged billet HT processed to the -O1... or directly to the -T7452?

Did the billet have material certifications from the processor? IE...

What was the forging spec? Was billet grain size/control/flow checked? Chemistry/hardness/conductivity/tensile Checks?

Was a thru-ultra sonic required... in multiple orientations... and to what class was the block rated? Typical ASTM B594

Was this the billet a one-of-a-kind... or was-it-one of many in a lot 'heat'?

Has the impeller been 'in-service'?

/NOTE/ 7050 is a well-studied alloy with there are many technical papers many ... but know basic info on the raw-stock is a big starter.

I design lots of replacement parts from 7050 forged block and plate... raw stock certifications are the starting point.

If find the concept of an aluminum 'impeller'... with high rotation speed and fluid thrust... and likely vibrations and/or cavitation... a bit unnerving.

My head hurts... thinking too hard about this...

Dhurjati Sen

Materials

Good to see that ASM Handbooks still rule.

ASM Handbook Volume 9: Metallography and Microstructures

www.asminternational.org

www.asminternational.org

ASM Specialty Handbook: Aluminum and Aluminum Alloys

www.asminternational.org

www.asminternational.org

ASM Handbook Volume 9: Metallography and Microstructures - ASM International

Volume 9 is recommended for anyone who specifies, performs, monitors, evaluates, or uses metallurgical analysis for production QC, research, or educational training. Important updates reflecting the substantial changes in automation, equipment, consumable products and preparation methodology, as...

ASM Specialty Handbook: Aluminum and Aluminum Alloys

ASM Specialty Handbook: Aluminum and Aluminum Alloys - ASM International

This one-stop reference is a tremendous value and time saver for engineers, designers and researchers who select and process aluminum and aluminum alloys. Covers all aspects of the selection, processing, properties, and performance of aluminum.

Similar threads

- Locked

- Question

- Replies

- 1

- Views

- 1K

- Locked

- Question

- Replies

- 2

- Views

- 2K

- Replies

- 5

- Views

- 891

- Replies

- 6

- Views

- 786

- Replies

- 12

- Views

- 876