Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations dmapguru on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Truss Top Chord Lateral Support 1

- Thread starter hoshang

- Start date

- Thread starter

- #61

English is my second language. I wrote didn't, and accepted, I meant we discussed the matter at the beginning of the design, not during the discussion in the eng-tips forum. The whole discussion on this forum is about top chord lateral support and it came to the global truss so that the box support would simulate two roller support at the ends and one hinge support at midspan (as in the analytical model). If you notice I wrote in earlier posts that the spans were 90ft.....

....

So how do these conversations with the architect go?

"Dear Mr. Architect, my sub-consultant who works for free at eng-tips.com suggested....."

Kudos to BA, man. Holy cow.

Hi BA,

Please notice I edited post #56.

Overall, how would you configure the box truss (as a support) to simulate roller support at the ends and a hinge support at midspan (as in the analytical model)? I mean assume you have a truss supported by two roller supports at the ends and a hinge support at midspan. How would you configure box trusses at the ends and midspan so it would simulate the support conditions in the analytical model (i.e., two roller supports at the ends and a hinge support at midspan)?

Last edited:

Your English seems fine to me. That is not the issue.English is my second language. I wrote didn't, and accepted, I meant we discussed the matter at the beginning of the design, not during the discussion in the eng-tips forum.

What makes you think that one hinge support at midspan is better than two?The whole discussion on this forum is about top chord lateral support and it came to the global truss so that the box support would simulate two roller support at the ends and one hinge support at midspan (as in the analytical model). If you notice I wrote in earlier posts that the spans were 90ft.

I wouldn't do that because it's the wrong approach.Hi BA,

Please notice I edited post #56.

Overall, how would you configure the box truss (as a support) to simulate roller support at the ends and a hinge support at midspan (as in the analytical model)?

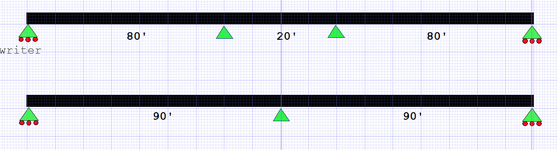

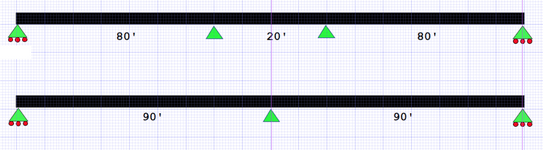

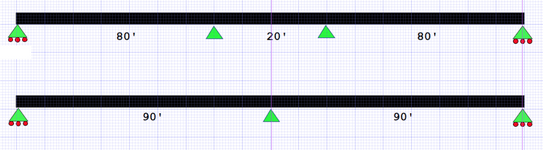

It should be apparent in the sketch below that:I mean assume you have a truss supported by two roller supports at the ends and a hinge support at midspan. How would you configure box trusses at the ends and midspan so it would simulate the support conditions in the analytical model (i.e., two roller supports at the ends and a hinge support at midspan)?

- For simple spans, truss moments are much lower with two pinned supports.

- For continuous spans, truss moments are much lower with two pinned supports.

- With two pinned supports, moment is easily resisted by the X-braced frame of large width.

- With two pinned supports, moment is applied to the box trusses which are not very stiff and bend over their height of about 20', causing instability of the structure. (Same for a line support.)

- With one pinned support, moment is not transferred to a stiff frame, but may act almost as a true pin because of the frame stiffness.

- With one pinned support, moment is not transferred to a box truss as suggested by OP. Horizontal forces or unbalanced gravity load cause instability unless the box truss is extremely stiff and fully fixed at foundation.

Attachments

- Thread starter

- #63

A column hinged top and bottom simulates a roller support. That is not the issue and the architect has already approved that.Hi BA,

Appreciate your help.

1- How would you configure a box truss to simulate a roller support in this image:

The architect has also approved a cross braced structure at midspan, but you are not content with that.

If you object to the diagonal braces, perhaps you would prefer a rigid frame adequate to resist horizontal forces parallel to the bridge. If so, problem solved.

My main concern is with seismic forces. I have no idea where this structure is situated, but we know that there has been a recent earthquake in Turkey, so be prepared to address that issue.

Interesting video...Maybe we should go for a cable stayed bridge...(just joking)I captured these images:

Hard to say what is intended here. The trusses are not symmetrical; on the right side there's no end diagonal, the top chord extends to an end vertical member which appears to align with the exterior of the supporting box truss. My guess is that it is intended to simulate a pin on the left and a roller on the right to permit temperature strain to occur easily, but it is an unusual detail. That would suggest two each truss top and bottom on the left. It is not clearly a roller on the right, but perhaps one top and two bottom each truss. I am tempted to say for the right end, one pin top and one pin bottom for each truss, but that leaves two legs of the box truss unattached. Let's just say it seems like a strange detail.The span is 27.75 m. How much pinned supports would you consider in an analytical model for this truss? One at each end or two at each end?

Others may see something that I missed in the photo; if so please contribute your thoughts.

Last edited:

- Thread starter

- #65

Can you elaborate more on the above?the top chord extends to an end vertical member which appears to align with the exterior of the supporting box truss. My guess is that it is intended to simulate a pin on the left and a roller on the right to permit temperature strain to occur easily

I can't get the above, can you explain it more?That would suggest two each truss top and bottom on the left. It is not clearly a roller on the right, but perhaps one top and two bottom each truss. I am tempted to say for the right end, one pin top and one pin bottom for each truss, but that leaves two legs of the box truss unattached.

No! Focus on your project, not on what someone else did!Can you elaborate more on the above?

No! My comments related to the photo of the bridge being erected across a road, see below.I can't get the above, can you explain it more?

In any case none of that is related to your project, so forget about it.

I think that whoever designed that bridge was trying for a pinned support on the left and a roller support on the right, but I'm not sure. Kindly stop filling the screen with photos of extraneous bridge details by others. They have nothing to do with your project.

- Thread starter

- #67

Similar threads

- Locked

- Question

- Replies

- 7

- Views

- 1K

- Locked

- Question

- Replies

- 9

- Views

- 2K

- Replies

- 6

- Views

- 5K

- Replies

- 3

- Views

- 3K

- Locked

- Question

- Replies

- 14

- Views

- 8K