Hi there,

It is my first time to check roof joists and not sure if I am right, please give me some advise.

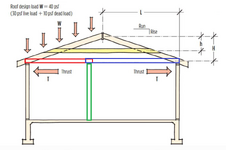

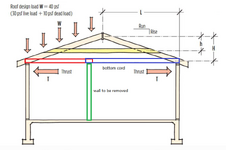

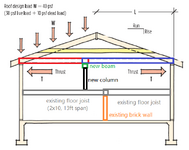

I have a client asking me the recommendation to replace a section of partition wall (2x4 studs, 16" o.c.) under the roof joists by using beam to support the roof joists (bottom cord of the roof truss structure). The roof joists (2x6, 16" o.c.) were not one piece spanning from perimeter wall to perimeter wall. They are two pieces attached together side by side (about 1.5ft overlapping) and supported by the partition wall close to the middle of the span. The partition wall sits on floor joist, not a beam. Also, there was no load bearing wall under this partition wall. For the roof truss, see attached pictures, they are simple triangle roof truss. Rafter 2x5, 16" o.c., colar tie 2x4, 32" o.c., bottom cord/roof joist 2x6, 16" o.c. My analysis is that the roof joist/bottom cord mainly under tension. So the partition wall just simply supports the roof joists from falling. In this case, how much load I should design for the beam? is 15psf dead load + 5psf live load enough? Am I correct for the roof joist analysis? Please give me some help. Thanks.

It is my first time to check roof joists and not sure if I am right, please give me some advise.

I have a client asking me the recommendation to replace a section of partition wall (2x4 studs, 16" o.c.) under the roof joists by using beam to support the roof joists (bottom cord of the roof truss structure). The roof joists (2x6, 16" o.c.) were not one piece spanning from perimeter wall to perimeter wall. They are two pieces attached together side by side (about 1.5ft overlapping) and supported by the partition wall close to the middle of the span. The partition wall sits on floor joist, not a beam. Also, there was no load bearing wall under this partition wall. For the roof truss, see attached pictures, they are simple triangle roof truss. Rafter 2x5, 16" o.c., colar tie 2x4, 32" o.c., bottom cord/roof joist 2x6, 16" o.c. My analysis is that the roof joist/bottom cord mainly under tension. So the partition wall just simply supports the roof joists from falling. In this case, how much load I should design for the beam? is 15psf dead load + 5psf live load enough? Am I correct for the roof joist analysis? Please give me some help. Thanks.