SALTRAM4567777

Structural

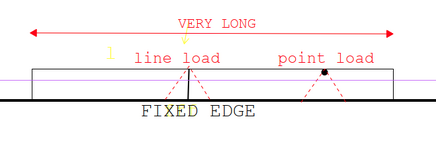

I have a cantilever plate rigidly clamped on one side and free on the other sides, with the plate being very long in the direction perpendicular to the cantilever span. For a point load applied near the free edge, I usually determine the required plate thickness considering load spread at 45 degrees. My question is, for a uniformly distributed load (UDL) along the length of the plate, how should the required thickness be calculated? Do we still apply the 45-degree load spread assumption, or is there a different approach for UDL in this case? Any guidance or references would be helpful.