@sdm919 Thank you for your willingness to help.

Note that SUPORT and SUPORT1 are different cards.

The reason I'm using SUPORT1 is because MSC Nastran documentation mentions it's mandatory to use it for buckling with inertia relief, instead of SUPORT.

My first question should have been: have you checked the model with a simple linear static run? This will ensure there are no other issues before attempting the INREL run. Set up a simple load/BC case and make sure it runs and the deflections and other results look reasonable.

I ran 4 different conditions:

-Model runs fine in the constrained linear static solution (number 1 listed below)

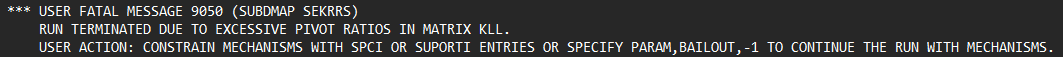

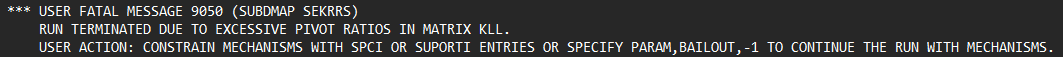

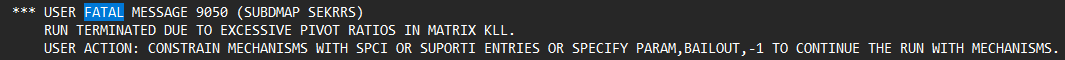

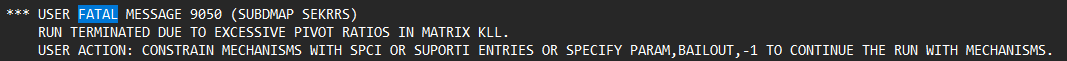

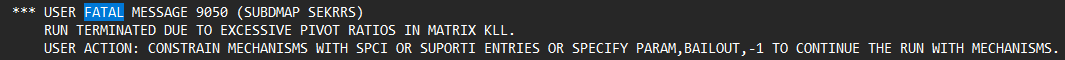

-Got a fatal error in run number 2, which is linear static solution with inertia relief, constrained as mentioned in the previous post (one node with 123, another one with 23, and last one with 3)

-Third run is the same as run number 2, except I changed the SUPORT1 constraint. It runs fine.

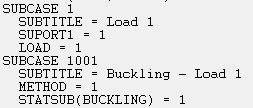

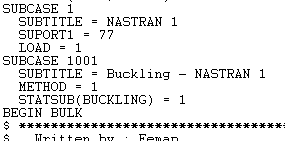

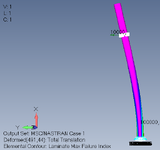

-Fourth run is the same as third run, except I added the buckling subcase, which calls the third run results using STATSUB.

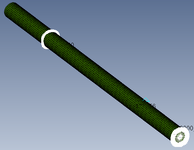

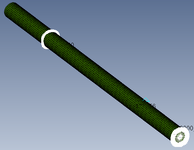

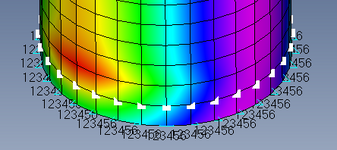

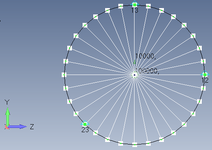

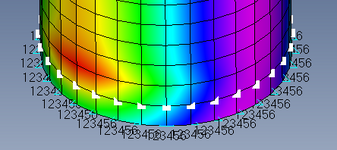

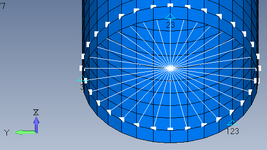

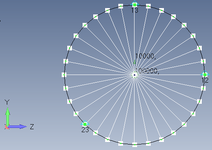

Run number 1: Using linear static analysis SOL 101. Cylindrical shell completely fixed at the bottom. The constraint is applied directly at the nodes of the cylindrical surface. The white squares are the RBE3 legs I'm using to apply an axial load at the center. There's another load at the top pointing towards +Y which causes bending of the structure.

Constraint

Load at the top

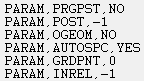

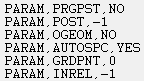

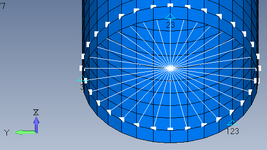

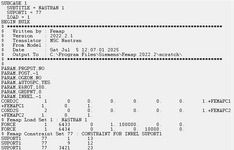

Run number 2: Also linear static analysis SOL 101 like run number 1, but using manual inertia relief INREL -1. Instead of running as default, I set up a subcase in the Case Control section. The subcase calls SUPORT1 = 77 (I put a picture of the .nas file below in the Run number 3 part).

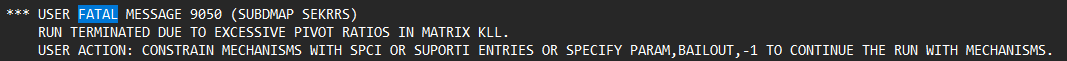

Constraint 77, which is used as SUPORT1: one node is 123, second node is 23 (this node is in line with +Z), and third node is 3 (this node is aligned with +Y). For some reason this gave me the exact same fatal error 9050.

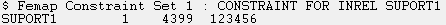

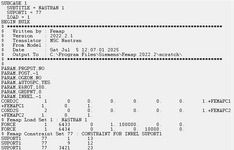

Run number 3: Exact same condition as run number 2, except I changed the SUPORT1 constraint as shown below. Doing this solved the fatal error. But I'm still trying to figure out why.

Constraint used as SUPORT1 has one node with 12 (in line with+Z), one node with 13 (in line with +Y), and another node with 23 (rotated 45 degrees from the main axis).

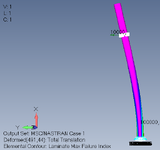

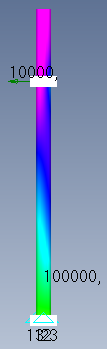

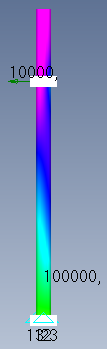

Laminate failure index contour:

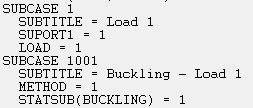

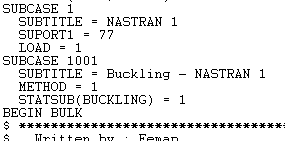

Picture of the .nas file showing SUPORT1 in the subcase. INREL and SUPORT1 are defined in the Bulk Data.

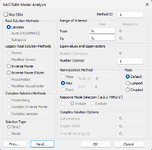

Run number 4: Using the exact same configuration as run number 3, I tried running buckling SOL 105. The only thing I did was include a new SUBCASE, which calls for the results of the linear static run using STATSUB. But despite the linear static case running perfectly fine, when I include the buckling subcase I get the fatal error again.

I see you have no solid elements, so my initial guess there was wrong. But CQUAD4 elements cannot take twisting moments normal to the element surface. [Example: If you had a flat plate modeled in the x-y plane, these elements cannot take Mz.] For your cylinder, these elements cannot take moments about the outward normals to the cylindrical surface (might be your global y or z axis or a combination depending on where around the perimeter the point is). If you decide to pursue this, you could add a ring of CBAR elements around the circumference at the location where you currently have your SUPORT1. Since your thickness appears to be 2.4, you could make the bar a square cross-section of dimensions 2.4x2.4. This would add rotational stiffness that the shells do not have - perhaps enough to get the model to run but not enough to seriously affect the results.

But the previous suggestion of supporting 3 nodes translationally is probably the best bet if you can get that to work (and your simple static runs shows no other issues).

Considering run number 3 worked above, the way I'm understanding the problem is inertia relief works fine with the SUPORT1 constraint used. Linear static SOL101 works fine and because of that I'm making an assumption inertia relief is working fine. The CBAR element around the circunference solution is interesting and I'll try it as soon as I can. But considering run number 3 worked, it's not necessary to use the CBAR. Do you agree?

For some reason buckling SOL 105 crashes with Fatal Message 9050 even if the linear static subcase with inertia relief is working fine. I'm wondering if there's anything different that should be done with SUPORT1 for the buckling subcase to work. But I don't thin that makes a lot of sense, since the way I undertand Nastran, because I'm using STATSUB, the buckling subcase is only using the results from the linear static subcase, which ran perfectly fine.

Do you have any idea what could be happening here?

If nothing works, another option might be to apply the inertia loads directly rather than using INREL to compute them. From the mass of your model and the known applied loads, you could back out the accelerations and apply them using GRAV and/or RFORCE cards.

I agree this could be done. But consider the cylinder shell structure is a rocket, which is actually what I'm trying to simulate... I'm wondering how to constraint the structure to simulate flight condition. Inertia relief seems to be the right way to do so. Maybe constraining at the CG could be another option.