Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations cowski on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

allowable stress value in creep region for 1.0345

- Thread starter rafaresma

- Start date

- Thread starter

- #2

Hi friends,

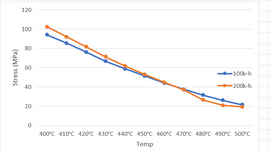

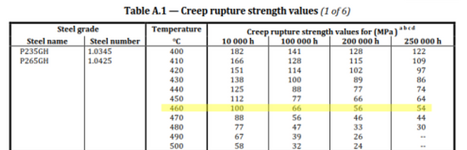

Why does the allowable stress for material 1.0345 in the Caesar II program appear to be greater at 200,000 hours of operation than at 100,000 hours of operation?

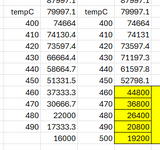

View attachment 14631

Doug Hunter

Automotive

What is the source of your values? What is happening the the test samples for 100,000 and 200,000 hours?

- Thread starter

- #4

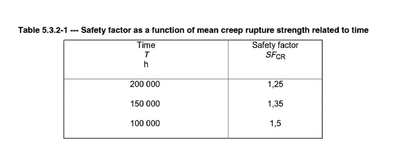

I got the values from caesar ii database (as seen below), actually in EN 13480 standard, it is said to take 1.5 safety factor for 100,000 working hours and 1.25 for 200,000 working hours, but this condition is an absurd result according to me because a higher allowable stress value is seem as a reference in the case of 200,000 hours of operation.What is the source of your values? What is happening the the test samples for 100,000 and 200,000 hours?

Best Regards

Bahri Elman

Piping Stress Engineer

If the EN standard requires a safety factor, I would hope the published data is with those safety factors applied? Or it otherwise says this is the raw data.

Is there a spelling error in the safety factor table? The hours listed don't line up with the material hours given. I would expect it to say SF for 10,000 hrs, following by 100k, 200k, 250k hrs based on that material table.

Is there a spelling error in the safety factor table? The hours listed don't line up with the material hours given. I would expect it to say SF for 10,000 hrs, following by 100k, 200k, 250k hrs based on that material table.

Last edited:

Doug Hunter

Automotive

I agree with RVAmeche that it is important to understand if the table values do, or do not, have the safety factor already applied.

It is also important to be clear on the assumptions for the data. What is actually happening over 100k or 200k hours? Is there a cycle assumed for temperatures and/or stresses, or is this a steady-state temperature creep situation?

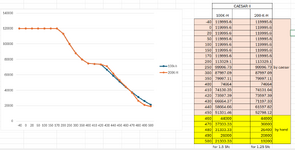

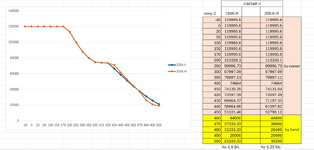

The table data is going to be very specific, compiled from detailed experience, where the safety factors are more general and rounded from a greater body of data. This could produce small apparent anomalies. That being said, the apparent discontinuity of the 480C and 490C points in the 200K curve are puzzling and cause for questioning. I would first check that you typed the data correctly into Excel. I would also chart the table values directly without any modification. You could then check that the Caesar values are in 100% agreement with the EN values. Then you could inquire with the EN governing body about a possible error.

It is also important to be clear on the assumptions for the data. What is actually happening over 100k or 200k hours? Is there a cycle assumed for temperatures and/or stresses, or is this a steady-state temperature creep situation?

The table data is going to be very specific, compiled from detailed experience, where the safety factors are more general and rounded from a greater body of data. This could produce small apparent anomalies. That being said, the apparent discontinuity of the 480C and 490C points in the 200K curve are puzzling and cause for questioning. I would first check that you typed the data correctly into Excel. I would also chart the table values directly without any modification. You could then check that the Caesar values are in 100% agreement with the EN values. Then you could inquire with the EN governing body about a possible error.

- Thread starter

- #7

If the EN standard requires a safety factor, I would hope the published data is with those safety factors applied? Or it otherwise says this is the raw data.

Is there a spelling error in the safety factor table? The hours listed don't line up with the material hours given. I would expect it to say SF for 10,000 hrs, following by 100k, 200k, 250k hrs based on that material table.

No, there is no mistake. I took these coefficients directly from the time-dependent design section of the EN 13480-3:2012 standard. Similarly, when I looked at the standard published in 2017, I saw that the safety factor was taken in the same way.

Also, the material database in the Caesar program also matches these values, but it seems to me that there is only a logic error. In the 100k hour case, it should give a higher allowable stress value, but it turns out to be lower. Frankly, this does not fit my head very well. I cant understanda this

- Thread starter

- #8

This is a time-dependent design calculation, not a cycle, but a system that will work continuously, for a life of 20 years, 200,000 hours, I am looking for the allowable stress of the material can according to the EN standard due to the creep event.I agree with RVAmeche that it is important to understand if the table values do, or do not, have the safety factor already applied.

It is also important to be clear on the assumptions for the data. What is actually happening over 100k or 200k hours? Is there a cycle assumed for temperatures and/or stresses, or is this a steady-state temperature creep situation?

The table data is going to be very specific, compiled from detailed experience, where the safety factors are more general and rounded from a greater body of data. This could produce small apparent anomalies. That being said, the apparent discontinuity of the 480C and 490C points in the 200K curve are puzzling and cause for questioning. I would first check that you typed the data correctly into Excel. I would also chart the table values directly without any modification. You could then check that the Caesar values are in 100% agreement with the EN values. Then you could inquire with the EN governing body about a possible error.

Actually, as you said, I compared the data via Excel, you can see it in the image below. Still, the same inconsistency occurs. I couldn't find the source of the inconsistency here, but we can be sure that the data is correct.

The allowable stress values that I marked in yellow are the data I calculated according to the EN standard, and the others are data taken from the database of the Caesar II program. But I only made calculations for temperatures above 450C because the allowable stress values of this material do not appear in the Caesar program for temperatures above 450C.

Attachments

- Thread starter

- #10

I actually I need this information if you can help me thank you very muchIf you have questions/concerns about the EN standard data I would try to contact a fabricator or someone who can tell you what their piping material properties are.

- Thread starter

- #12

I understand I will contact the manufacturer as you said, thank you for the discussionI meant if you know who's buying/sourcing the material, ask them for detailed material property information (assuming new construction). That's not commonly something my company gets involved with so I don't have any leads for that.

Similar threads

- Locked

- Question

- Replies

- 2

- Views

- 718

- Locked

- Replies

- 3

- Views

- 3K

- Replies

- 10

- Views

- 815

- Locked

- Question

- Replies

- 6

- Views

- 827