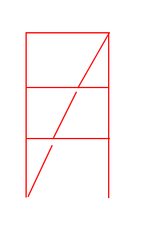

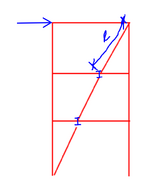

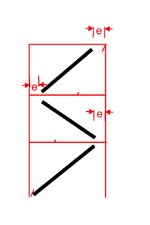

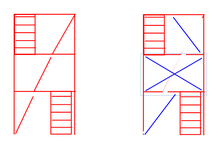

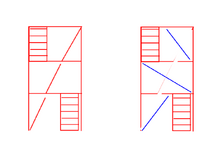

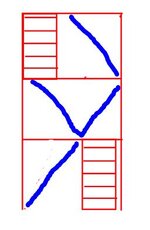

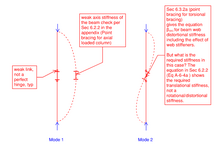

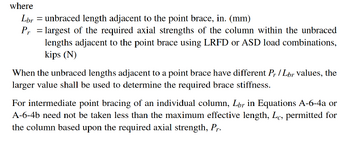

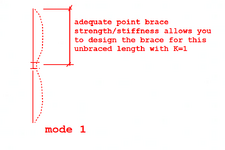

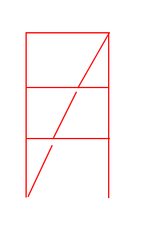

The vertical bracing layout should follow the configuration shown in the snippet below. Since the compression force is continuous through the bracing members, gusset plates, and beam webs, I believe I need to verify whether the weak-axis stiffness of the beam is sufficient to brace the bracing member per Appendix 6. I'll also need to check beam shear.

Am I missing any other critical checks?

Am I missing any other critical checks?