This article on the 787's AD to fix software issue from 2015, shows 787's are not just more fly-by-wire, but are much more software controlled, which can have some unique latent defects, once the holes line up.

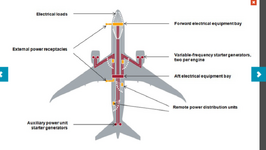

"According to the AD, if the 787’s power control units are operated for eight months (248 days) continuously, a software glitch can shut down the entire aircraft’s electrical system, which can result in a complete loss of aircraft power. This could even happen mid-flight."

Simulation reveals failure mode without risk to aircraft

www.engineering.com

More on new software power failure, May 1, 2025 article. Not sure if this is same as 2015 AD or not at this point.

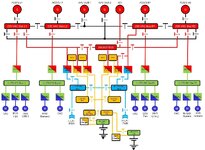

"This AD was prompted by the determination that a Model 787 airplane that has been powered continuously for 248 days can lose all alternating current (AC) electrical power due to the generator control units (GCUs) simultaneously going into failsafe mode," the memo stated. "This condition is caused by a software counter internal to the GCUs that will overflow after 248 days of continuous power. We are issuing this AD to prevent loss of all AC electrical power, which could result in loss of control of the airplane."

"The memo went on to say that Dreamliners have four main GCUs associated with the engine mounted generators. If all of them were powered up at the same time, "after 248 days of continuous power, all four GCUs will go into failsafe mode at the same time, resulting in a loss of all AC electrical power regardless of flight phase."

Beware of integer overflow-like bug in aircraft’s electrical system, FAA warns.

arstechnica.com

And here is another new reboot every 51 days AD from 2020. A lot of timely rebooting seems to be required to keep 787's flying....

US air safety bods call it 'potentially catastrophic' if reboot directive not implemented

www.theregister.com

And Radio Software Issues on going. April 2025 article.

Boeing is facing ongoing challenges with its 787 Dreamliner's radio communication problems, even after attempted software fixes.

aviationa2z.com

I have to hard reboot my wife's robovac periodically when it starts acting erratic.... But risks of loss are low for that failure.......

And then there are reports of AI having maintenance issues. They received the AI-171 plane in 2012.

Airliner identical to plane that crashed last week was forced to turn back an hour into flight from Mumbai to London

www.telegraph.co.uk

www.theguardian.com

www.theguardian.com