Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations JStephen on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

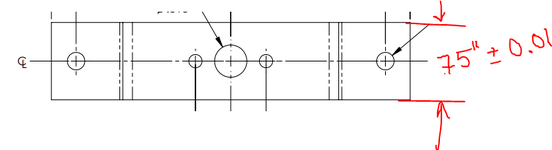

Symmetric to Centerline note is given to below drawing attached, need to understand how manufacturer will punch the holes at what tolerance.

- Thread starter Charan@

- Start date

jamiethekiller

Mechanical

- May 2, 2025

- 20

put a datum flag on .75 +/- .01. make the holes in position to that datum by whatever tolerance you want them to do.

- Thread starter

- #5

can't we consider the width size .75 +/- .01 and ask manufacturer to maintain half the size for Centerline location ? Ex: .76/2 , .75/2, .74/2 or is it mandatory to show dimension of centerline from one end with tolerance?There's no tolerance for the location of the holes relative to the width. "Their best" is the standard that will be applied.

- Thread starter

- #6

does it means the dimension for the hole position not needed, if not what will be the tolerance will manufacturer control.Position tolerances of these holes depend on width tolerances and its straightness due to your material's camber.

There are solutions, proposed above, but I was answering the original question, which is why there were solutions proposed above.can't we consider the width size .75 +/- .01 and ask manufacturer to maintain half the size for Centerline location ? Ex: .76/2 , .75/2, .74/2 or is it mandatory to show dimension of centerline from one end with tolerance?

Even if you ask to maintain half the size, that won't be perfect, so how close to half is acceptable? Position tolerancing is the typical approach to describing the tolerance for deviation from the center by describing which center is to be used to measure relative to and how far the hole center can be from it.

mfgenggear

Aerospace

As stated before, datums added to the width and length. A true position with fcf typ on all holes.does it means the dimension for the hole position not needed, if not what will be the tolerance will manufacturer control.

A composite true position to all holes . Would be helpful.

does it means the dimension for the hole position not needed, if not what will be the tolerance will manufacturer control.

No, you don't need the "half" dimension. But you do need a position FCF to locate those holes to your datum which is width of the material. It sounds like you are not familiar with blanking operation of dies on press. There is a stripper in the die which looks like a tunnel. This tunnel is wider than your max. material width. The clearance is to handle the camber of the material (coil). So, that means the material will move in the die. Your punch is right in the middle of the stripper, but the material will shift, thus cause the deviation of the position. The narrower the material, the wider the position tolerance of those holes needs to be.

Last edited:

mfgenggear

Aerospace

OP

The holes on center line will not or may not be exact on center.

As posted above there are stack up tooling tolerances. So there needs to be ample suitable tolerance for manufacturing. If it needs to be tighter tolerance then it becomes a expensive machining operation.

Sheet metal location tolerance have to be liberal.

Sheet metal can be sheared, laser cut, water jet cut, or punched. The holes if hole to wall thickness can be punch in one hit. The periphery

If punch has to be multiple striper cuts. So let's not perfect. A sheared cut is in one cut.

So can be more precise. Rules of thumb but

All rules can be broken.

The holes on center line will not or may not be exact on center.

As posted above there are stack up tooling tolerances. So there needs to be ample suitable tolerance for manufacturing. If it needs to be tighter tolerance then it becomes a expensive machining operation.

Sheet metal location tolerance have to be liberal.

Sheet metal can be sheared, laser cut, water jet cut, or punched. The holes if hole to wall thickness can be punch in one hit. The periphery

If punch has to be multiple striper cuts. So let's not perfect. A sheared cut is in one cut.

So can be more precise. Rules of thumb but

All rules can be broken.

Dean Watts

Mechanical

I'm late to the discussion, but will still add that I see no mention of the need for either the top or bottom planar surface, through which the holes are cut, to be specified as the primary datum feature, then the width and length could be the secondary and tertiary datum features. The two rotations that the larger planar primary will constrain are very important for the position tolerances that need to be added to the holes. A sheetmetal part does not have sufficient thickness to enable the width of the part to be an adequate primary datum feature.

There's no compelling reason not to ID the needed datum features, then specify a position tolerance on the holes. No need to reinvent the wheel with some other tolerancing method.

Another way to describe this situation is that a center line marked on a drawing, or referred to in a note, has no power to control anything. At best/most it may help users understand that the drawing is showing.

There's no compelling reason not to ID the needed datum features, then specify a position tolerance on the holes. No need to reinvent the wheel with some other tolerancing method.

Another way to describe this situation is that a center line marked on a drawing, or referred to in a note, has no power to control anything. At best/most it may help users understand that the drawing is showing.

Even if a thin sheet metal part have did have some thickness for the depth of the part (or bends as implied in the OP image,) small variations possible in the small ends could let the part rotate considerably, where, thanks to trigonometry, the hole spacing along the surface could be very different than the desired hole spacing and the holes become elliptical.

Mainly academic because almost always the people making the parts will orient them to the largest flat surface that the holes penetrate even without any datum feature guidance.

Another confounding factor is that some of the holes are likely to control the secondary and tertiary orientation of the part and so it would make more sense for those holes to be the secondary datum feature to a feature control frame that uses a profile of surface geometric characteristic symbol to control where the sides and ends are relative to them.

Mainly academic because almost always the people making the parts will orient them to the largest flat surface that the holes penetrate even without any datum feature guidance.

Another confounding factor is that some of the holes are likely to control the secondary and tertiary orientation of the part and so it would make more sense for those holes to be the secondary datum feature to a feature control frame that uses a profile of surface geometric characteristic symbol to control where the sides and ends are relative to them.

mfgenggear

Aerospace

If the holes are machined simultaneously.

There's no problem machining to each other.

The issue will the edge distance to the ends

Keeping it consistant.

There's no problem machining to each other.

The issue will the edge distance to the ends

Keeping it consistant.

Dean Watts

Mechanical

I agree with 3DDave. If the holes on each end are the locating features, then I would choose them as datum features B and C, or as a pattern they could be datum feature B, if they have equal importance in located the part. It is likely that outer edges touch nothing but air. If so, then they are not the best choice for datum features. Function should almost always drive the choice of datum features.

Choosing the width and length as the secondary and tertiary datum features introduces a tolerance stack for the holes in the center of the part.

Controlling the holes in the center relative to the outer holes instead means direct control of the likely functional need (holes in the center of the part located with respect to the a DRF that uses the outer holes as the secondary and tertiary datum features), with no tolerance stack introduced. Controlling the width and length relative to the same datum reference frame, with size and position or profile, that can likely be relatively loose also makes sense.

Choosing the width and length as the secondary and tertiary datum features introduces a tolerance stack for the holes in the center of the part.

Controlling the holes in the center relative to the outer holes instead means direct control of the likely functional need (holes in the center of the part located with respect to the a DRF that uses the outer holes as the secondary and tertiary datum features), with no tolerance stack introduced. Controlling the width and length relative to the same datum reference frame, with size and position or profile, that can likely be relatively loose also makes sense.

Dean Watts

Mechanical

Yes, I think so. It looks like datum feature A would be two planar surfaces at the outer ends, with a raised surface between them. The two outer holes could be "B" as a 2X pattern if they're the same diameter, or one could be B and the other C, for B-C. Then the three holes in the center and the outer edges (faces) could be controlled with size and position.So, A primary| B-C | secondary is the way to go? Where A is a planar surface and B and C are the holes shown in the OP's picture.

Then the width could be positioned to |A|B-C|

Datum feature A, since it is two surfaces would need to be controlled with either flatness with a continuous feature modifier added, or with surface profile. The two outer holes would need a position tolerance that references datum feature A.

Burunduk

Mechanical

- May 2, 2019

- 2,582

And I would add to what Dean said that when 2 or more holes are used to establish a datum as a pattern or as a common datum feature, it is almost always approriate to reference it at MMB, to invoke fixed size datum feature simulator (such as 2 pins of fixed diameters on an inspection fixture).

This is because datum references should mimic the functional assembly and most likely that the holes will mate to constant-diameter fasteners. The benefit is datum shift - which will potentially allow more functional parts to pass and will also enable making a simlple inspection device as a functinal gage.

If due to considerations related to the inspection method a simulator made of two largest-inscribed cylinders is preferable (such case may be when the inspection choice is a CMM, for which applying datum shift may be complicated), one could always inspect the requirement as if it was referencing the datum at RMB. It would simply be a stricter inspection that may reject some good parts, but it wouldn't accept any parts that are non-conforming to the drawing requirement.

This is because datum references should mimic the functional assembly and most likely that the holes will mate to constant-diameter fasteners. The benefit is datum shift - which will potentially allow more functional parts to pass and will also enable making a simlple inspection device as a functinal gage.

If due to considerations related to the inspection method a simulator made of two largest-inscribed cylinders is preferable (such case may be when the inspection choice is a CMM, for which applying datum shift may be complicated), one could always inspect the requirement as if it was referencing the datum at RMB. It would simply be a stricter inspection that may reject some good parts, but it wouldn't accept any parts that are non-conforming to the drawing requirement.

Similar threads

- Question

- Replies

- 3

- Views

- 2K

- Solved

- Replies

- 13

- Views

- 1K

- Locked

- Question

- Replies

- 7

- Views

- 5K

- Locked

- Question

- Replies

- 15

- Views

- 6K

- Replies

- 22

- Views

- 2K