If there is an obvious concern why must a message be sent anonymously?

A friend of mine and I noted another issue that has not been mentioned before. He sent Steve an email asking if the shim in the center of the baseplate was removed prior to grouting. He works with structures but is not licensed. He complimented the appearance twice I think in his email. The friend gave a very brief explanation of why he was so concerned that he felt he should contact him. He requested Steve to respond and let him know if it had been removed so he could put the issue to rest in his mind. The entire response was ‘It was removed”. That seemed strange to me when I saw the response. No, thanks for your concern, thanks for giving me a heads up, thanks for having my back, yes I did remove it because I knew it would create a problem or thanks for the compliment on the appearance, just “It was removed”. Maybe he was very busy but wanted to respond, we have no idea. He did not mention this thread and I would not have either at this stage.

Connections like this are one of the harder ones to design. A lot of parameters, mixing of materials of different strengths and different codes. We hope he truly removed the shim but he was given a heads-up on that issue. Someone who already knows about the ramifications of the shim being present, should know about basic embedment lengths, length of rebar needed to develop strength and other parameters more common than the presence of a shim. These are generally in any book on the subject, whereas the presence of shims is probably never mentioned, we just have it trigger something in our mind when we notice them.

Honestly, we have no real idea what is really there in the field, this is speculation at best in some areas, but some items are definitive (such as no redundancy, but redundancy is not an absolute requirement to my knowledge).

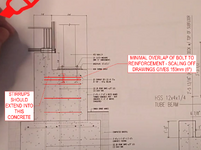

Rotation highly controls this connection design. The shim is one thing that appears minor if you are considering vertical loads, but when considering rotation, it is much more critical. The drawing does not show a leveling nut on the baseplate and the pictures do not appear to show a leveling nut, yet there is a gap between the baseplate and the concrete footing. Something must be holding the 2 apart, and it is not grout since no grout is visible. In one portion of the video (6:30 into video) you can see shims present. The shim in the middle of the column appears to bear on the steel but the ones at the side of the column away from the house appear to have a gap between them and the baseplate. They may be just lying on the footing. They are a stack of thinner shims.

In other pictures (4:50 in), you can clearly see the shims on the side away from the house are not there anymore, but there is no grout and the gap is still present and the hoist has been removed from the deck. So, we are assuming the center shim is still there. At 35 seconds into the video, you can see a shim in the center of the baseplate. It would have been twice as good to use shims at the side away from the house only, rather than in the center. No shims are needed on the side towards the house, that level is controlled by the nut on top of the plate due to the rotation direction. If I knew all of that, why would I put one in the center that later will be VERY hard to remove? Whatever tension is placed on the bolts due to dead load will be twice the magnitude due to the short moment arm. You cannot reduce this tension without prying up on the opposite side while grouting and allowing the grout to cure before releasing the prying mechanism. Now, how hard the grout gets “packed in” matters a lot if there is already a loaded stout steel shim in direct bearing. At a minimum, the tension load due to DL is twice what someone may have estimated. If the shim still controls rocking after the grout is installed, the moment arm is still cut in half (or at least reduced), thus increasing (up to double) the tension in the bolts from LL. They may have wedged the outside prior to grouting, removed the center shim, grouted professionally, removed the tapered wedges after the grout cures for several days and touched up the grout. We have no way of knowing. But this would be VERY difficult to do since the shim appears to be in the center of the plate.

Are we correct about what a shim does to the moment arm?

As far as having some redundancy, they could have cast an embedded steel plate into the vertical foundation face and attached to it with a strap or gusset.

In his video, he says anchor bolts “deep” into the footing, but what is visible to us is not considered deep. He also is reading off his call-out for the 12x4 tube. He refers to it as “High-Strength Steel” which I assume is the HSS on his note. HSS stands for “Hollow Structural Section” and is the standard notation for calling out a hollow tube. Small things like this increase concern.