struct_eeyore

Structural

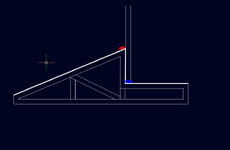

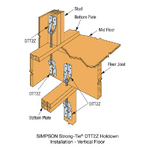

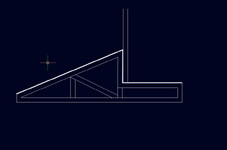

I'm trying to resolve a wonky diaphragm on a truss with a ~2'-0" vertical step.

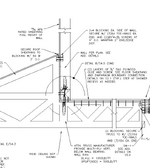

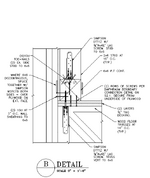

The diaphragm can be loaded in both directions. Exterior sheathing is 19/32, interior will be (2)layers of 3/4.

We're obviously loosing the benefit of stagger lapping at least in one direction, but conservatively both.

Other than trying to fit a continuous 2x to connect the plywood corners, are there any other considerations here?

(Chords at outer boundaries have been resolved)

The diaphragm can be loaded in both directions. Exterior sheathing is 19/32, interior will be (2)layers of 3/4.

We're obviously loosing the benefit of stagger lapping at least in one direction, but conservatively both.

Other than trying to fit a continuous 2x to connect the plywood corners, are there any other considerations here?

(Chords at outer boundaries have been resolved)