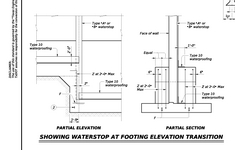

Building codes typically have guidelines on max vertical rise over run. But typically for bridges you will have a construction joint at the step. AASHTO should provide guidance if you have access to the code. Some details will show an actual step and others will slope the bottom. Not really sure it’s worth stepping a footing for a temporary structure. As for actual design I am not aware of anything special to the steps itself. Footing of this nature are designed in unit lengths so length wise the reinforcement is really temperature and shrinkage steel. Alternatively tee walls might be more appropriate for this type of work, they just use a leveling pad, you can check out their standard details. I think PA dot has good details. Maybe share more info on what the step is like and the structure that sits on it. As an intern I would hope you can also ask this from your manager or coworkers, but also know that doesn’t always workout. But good on you for seeking knowledge and taking initiative.