I'm familiar with Blodgett and his method to treat welds as a line. And I have looked at his example weld shapes in his manual, of which there are roughly a dozen (image below). But they are all simple typical shapes.

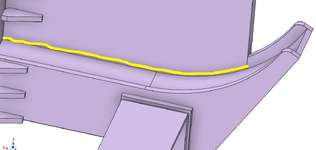

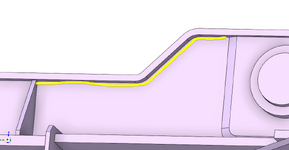

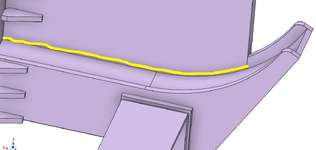

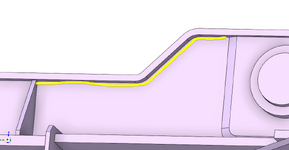

My question is how to apply the method to atypical shapes. Below are a couple example images. If the curved yellow lines represent fillet welds, is there a way to use Blodgett to size them?

My question is how to apply the method to atypical shapes. Below are a couple example images. If the curved yellow lines represent fillet welds, is there a way to use Blodgett to size them?