Pretty Girl

Structural

- Nov 22, 2022

- 153

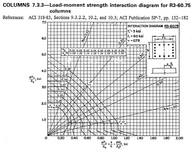

This chart is located in the book "Deep Surface" by Harshana Wattage, pg 148, about biaxial N-M interaction in columns. Their chart mentions something like Rm line, but I have seen these kind of lines in other old charts and they call it a different name. Most probably it refers to the same line. The book provides a way to calculate the lines and other things. But I'm not quite sure why do we need these lines. Can't we just be below the lines and call it a safe column design? I feel like we can even calculate the asfyk/ bhfck etc without those lines. What's the actual use of those?