Hi!

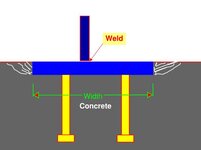

We know well embed plates will expand and concrete sometimes cracks due to excessive welding heat.

Is there any method to check if welding heat will cause concrete spalling around the embed plates?

Based on this method, can I decide plate size in addition to stress/strength analysis to avoid spalling/crack

as wider plates can dissipate welding heat easily?

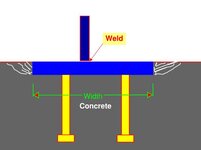

We know well embed plates will expand and concrete sometimes cracks due to excessive welding heat.

Is there any method to check if welding heat will cause concrete spalling around the embed plates?

Based on this method, can I decide plate size in addition to stress/strength analysis to avoid spalling/crack

as wider plates can dissipate welding heat easily?