M

mgeorgiadis

Guest

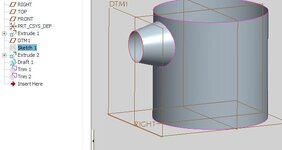

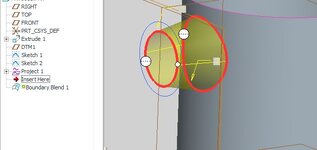

Hi I'm trying to create a VSS of a closed profile along a curved (cylinder) surface. Using Creo 2.

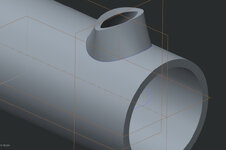

What I'm trying to model is a nozzle which is attached to a cylindrical vessel.

I create a parallel plane using the main planes going through the center of the main cylinder and on the new plane I draw a circle and project it onto the cylinder.

Next I select this projected curve as my trajectory and draw in the cross section of the nozzle.

When it is complete the result is not parallel nozzle walls as in the picture.

There are other (obvious) ways to model a nozzle but I really want to get this right so I can start to model the welds that join the nozzle to the cylinder because I can't get the results I want with Pro Weld tools.

Thanks to all in advance.

MikeG

I tried to upload the file but it says "Invalid file" so I couldn't

View attachment 6138

What I'm trying to model is a nozzle which is attached to a cylindrical vessel.

I create a parallel plane using the main planes going through the center of the main cylinder and on the new plane I draw a circle and project it onto the cylinder.

Next I select this projected curve as my trajectory and draw in the cross section of the nozzle.

When it is complete the result is not parallel nozzle walls as in the picture.

There are other (obvious) ways to model a nozzle but I really want to get this right so I can start to model the welds that join the nozzle to the cylinder because I can't get the results I want with Pro Weld tools.

Thanks to all in advance.

MikeG

I tried to upload the file but it says "Invalid file" so I couldn't

View attachment 6138

Attachments

Last edited: