mariolucas75

Civil/Environmental

Dear All,

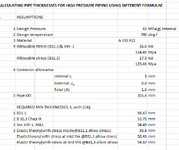

For pipe thickness calculations:

API 574 says for metallic pipe for which t ≥ D/6 or P/SE > 0.385 requires special consideration.

What is this special consideration? Where shall i find it ?

ASME 31.3 Para 304 Straight pipe under internal pressure says:

For t ≥ D/6 or for P/SE > 0.385, calculation of pressure design thickness for straight pipe requires special consideration of factors such as theory of failure, effects of fatigue, and thermal stress.

So, ultimately where is this formula available for thick wall / higher pressure (t ≥ D/6 or for P/SE > 0.385) pipe wall calculations ?

Thank you

For pipe thickness calculations:

API 574 says for metallic pipe for which t ≥ D/6 or P/SE > 0.385 requires special consideration.

What is this special consideration? Where shall i find it ?

ASME 31.3 Para 304 Straight pipe under internal pressure says:

For t ≥ D/6 or for P/SE > 0.385, calculation of pressure design thickness for straight pipe requires special consideration of factors such as theory of failure, effects of fatigue, and thermal stress.

So, ultimately where is this formula available for thick wall / higher pressure (t ≥ D/6 or for P/SE > 0.385) pipe wall calculations ?

Thank you