Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations JAE on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thermowell for small size pipes

- Thread starter Nejim

- Start date

- Status

- Not open for further replies.

1: can you put the thermowell in an elbow and use the inline pipe for the thermowell? Check your standards or Google elbow thermowell standards.

2: do you mean nozzle extension from vessel wall? 8” (200 mm) is very common, but I’ve seen “as short as possible” up to 12”. I’ve never seen 1800 mm.

2: do you mean nozzle extension from vessel wall? 8” (200 mm) is very common, but I’ve seen “as short as possible” up to 12”. I’ve never seen 1800 mm.

CGonsalves

Mechanical

My knowledge only applies to piping designed per ASME B31.1 and B31.3, and thermowells designed per ASME PTC 19.3-TW.

Q1: In our industry, we will either

A) increase the pipe size to 4", then install a thermowell with 2.5" insertion, and then decrease the pipe back to its original size, or

B) install the thermowell into a coupling coming off of the tee. We do need to watch out for the IDs of these couplings, however.

We typically use method B, but only because these pipelines are in steam drain service in those instances and are not necessarily subject to the requirements of PTC 19.3-TW.

I do not have an answer for Q2, but I question whether you would actually have a need for a nozzle that long. Is this an issue with accessibility?

Q1: In our industry, we will either

A) increase the pipe size to 4", then install a thermowell with 2.5" insertion, and then decrease the pipe back to its original size, or

B) install the thermowell into a coupling coming off of the tee. We do need to watch out for the IDs of these couplings, however.

We typically use method B, but only because these pipelines are in steam drain service in those instances and are not necessarily subject to the requirements of PTC 19.3-TW.

I do not have an answer for Q2, but I question whether you would actually have a need for a nozzle that long. Is this an issue with accessibility?

- Thread starter

- #5

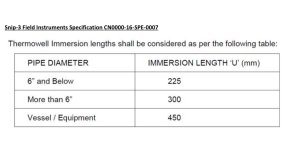

Attached is the client specs in an Oil&Gas project where they insists 225mm thermowell insertion lengths for 6inch and below sized pipes.

Attached is the client specs in an Oil&Gas project where they insists 225mm thermowell insertion lengths for 6inch and below sized pipes.My question about nozzle length (nozzle projection) has arisen as there are couple of nozzles on a vessel with unusual projections, vessel vendor clarify that the thermal load calculation demands such lengths and they cannot make any changes,

It very much depends on the application. If the restriction to flow created by the thermowell in an NPS2 pipe is not a concern, then you don't need to do any size changes. If it is a concern, going up to 6" seems pretty excessive, I wouldn't see a need to go any bigger than NPS3 or NPS4.

You can also look at thermowells that are narrower or otherwise designed to create less of a flow restriction, of course considering the mechanical requirements of the application, as well as any wake frequency concerns from PTC 19.3-TW.

Is this for a gas or liquid flow application? Gas flow you are less likely to have problems if you don't increase the line size.

1800 mm seems pretty long for a vessel nozzle, but without knowing anything else about your application it's difficult to say if it's too long. It also depends on the diameter - a very long and skinny nozzle is going to have bending concerns, but if the ratio of diameter to length is proportional to typical ratios for smaller nozzles it's not much of a concern from a mechanical standpoint.

You can also look at thermowells that are narrower or otherwise designed to create less of a flow restriction, of course considering the mechanical requirements of the application, as well as any wake frequency concerns from PTC 19.3-TW.

Is this for a gas or liquid flow application? Gas flow you are less likely to have problems if you don't increase the line size.

1800 mm seems pretty long for a vessel nozzle, but without knowing anything else about your application it's difficult to say if it's too long. It also depends on the diameter - a very long and skinny nozzle is going to have bending concerns, but if the ratio of diameter to length is proportional to typical ratios for smaller nozzles it's not much of a concern from a mechanical standpoint.

goutam_freelance

Mechanical

Some reputed company standards permit use of Tee or elbow but only if they are in vertical plane. Alternatively, the pipe size to be increased to min 3 in (depending on insertion length requirement) using reducer/expander and the thermowell can be in an inclined position wrt pipe CL to optimize the space available.

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 11K

- Question

- Replies

- 2

- Views

- 591

- Question

- Replies

- 13

- Views

- 12K

- Locked

- Question

- Replies

- 10

- Views

- 1K

- Locked

- Question

- Replies

- 6

- Views

- 4K