Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations JStephen on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Strut and tie design for pilecap with axial and shear load 6

- Thread starter mte12

- Start date

-

2

- #2

milkshakelake

Structural

CRSI Design Guide for Pile Caps say that strut and tie model is unconservative for pile caps because other modes of failure can control. For that reason, they don't present the strut and tie model. So if one of the biggest authorities on pile caps don't use it, I wouldn't use it. Or theoretically, you could use it and check all the failure modes manually as well.

-

1

- #3

Just Some Nerd

Structural

Curious as I don't have access to that design guide, what sorts of pile cap configurations/failure modes are they referring to? Wondering if that's for smaller scenarios (e.g. 2 or 3 piles) or larger pile cap groupsCRSI Design Guide for Pile Caps say that strut and tie model is unconservative for pile caps because other modes of failure can control.

- Thread starter

- #4

-

2

- #5

HTURKAK

Structural

- Jul 22, 2017

- 3,401

Can you post a sketch ? Is the question is for STM design of pile cap ? Or pedestal ?an example of a strut and tie design for pilecap with axial load as well as shear load at top of pedestal?

My points are ,

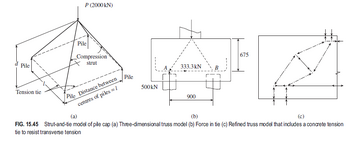

-ACI 318 allows the use of STM for deep pile caps .( R13.2.6.5 An example of the application of this provision is a pile cap similar to that shown in Fig. R13.1.1. Pile caps may be designed using a three-dimensional strut-and-tie model satisfying Chapter 23...)

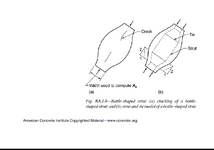

- There are experimental results that clearly indicates that the STM predicts the behaviour of deep pile caps more accurately. There could be modelling problems of the strut elements with a single compression element. The compression force at struts in deep pile caps in general is not the reason for failure by crushing of concrete. But failure occurs after the compression strut splits longitudinally due to transverse tension caused by spreading of the compressive stresses.

- This can be seen with a refined strut-and-tie model as shown in below Fig. 15.45(c) copy and paste from NARAYANAN,

- The use of transversal reinf. will improve the resistance ,

- Other failure modes should also be checked as MILKSHAKELAKE pointed out.

I have attached two documents for STM modelling issues and worked examples.

Attachments

milkshakelake

Structural

The ACI 318 provision HTURKAK mentioned is for allowing S&T analysis for deep pile caps, which is when the top of the pile cap is more than 0.5 times the distance in plan from center of column to center of nearest pile. I think this would apply for most pile caps. Maybe not ones for light piles, like helical piles.

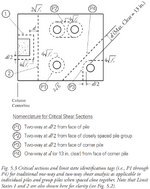

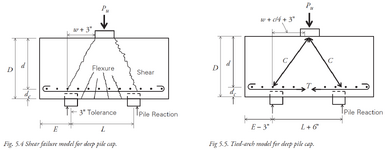

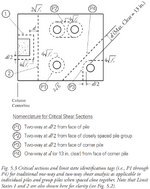

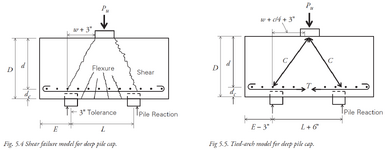

CRSI has the following limit states to check. Some of them are based on the column (limit states 1 to 6) and others at the pile (P1 to P4). Some of them are deep beam shear. I use an enveloped approach with FEM and also checking the limit states.

Source: CRSI Design Guide for Pile Caps first edition.

There is also a tied-arch failure mode near the column. CRSI recommends 180 degrees hooks as a precaution against this failure mode. Though in my experience, contractors find it difficult to make these hooks, especially with larger diameter rebar.

Edit: I'm not sure what codes AU uses, but there are spreadsheets published by CRSI. It's not very useful without the CRSI guide, but it's a taste: https://www.crsi.org/supplement-dg-for-pile-caps/

CRSI has the following limit states to check. Some of them are based on the column (limit states 1 to 6) and others at the pile (P1 to P4). Some of them are deep beam shear. I use an enveloped approach with FEM and also checking the limit states.

Source: CRSI Design Guide for Pile Caps first edition.

There is also a tied-arch failure mode near the column. CRSI recommends 180 degrees hooks as a precaution against this failure mode. Though in my experience, contractors find it difficult to make these hooks, especially with larger diameter rebar.

Edit: I'm not sure what codes AU uses, but there are spreadsheets published by CRSI. It's not very useful without the CRSI guide, but it's a taste: https://www.crsi.org/supplement-dg-for-pile-caps/

Enhineyero

Structural

I have designed pile caps using the method that milkshakelake mentioned. The main use of strut-tie then is to get the amount of tension reinforcement and check the concrete strut (similar to short column formula, without reinforcement).

The current info on strut-tie requires 'bursting' reinforcement and carry out additional node capacity check.

It begs to ask the question are all the pile caps that we have designed without bursting reinforcement not fit for purpose?

The changes in codes/standards, particularly in concrete, are normally brought about by observed failure (i.e. NZ Christchurch earthquake), because of this I appreciate the changes in concrete detailing for seismic compliance. However, I cant seem to find the history of STM and why its model has continuously changed. Are there any pile caps or deep transfer beams/walls that failed because of node failure or bursting strut failure?

The current info on strut-tie requires 'bursting' reinforcement and carry out additional node capacity check.

It begs to ask the question are all the pile caps that we have designed without bursting reinforcement not fit for purpose?

The changes in codes/standards, particularly in concrete, are normally brought about by observed failure (i.e. NZ Christchurch earthquake), because of this I appreciate the changes in concrete detailing for seismic compliance. However, I cant seem to find the history of STM and why its model has continuously changed. Are there any pile caps or deep transfer beams/walls that failed because of node failure or bursting strut failure?

-

1

- #8

HTURKAK

Structural

- Jul 22, 2017

- 3,401

If the compression strut is confined with plain concrete , ( as the case in pile caps ) , the compression stress should be limitedIt begs to ask the question are all the pile caps that we have designed without bursting reinforcement not fit for purpose?

to avoid transverse splitting in concrete. The sittuation is different for deep beams which they have web mesh reinforcement.

AFAIK , the truss model studied almost a century ago and improved by MÖRSCH in 1909 . The model is called Ritter - MÖRSCH truss model. ( I have an old concrete book states this ( Vorlesungen über Massivbau by LEONHARDT ).However, I cant seem to find the history of STM and why its model has continuously changed. Are there any pile caps or deep transfer beams/walls that failed because of node failure or bursting strut failure?

Todays STM rules were mainly provided by Schlaich and co-researchers. (1982,87 ..) I have the book =Toward a Consistent Design of Structural Concrete ( By Jorg Schlaich, Kurt Schafer, Mattias Jennewein 1987)

An again AFAIK , the STM proposed by ACI in ACI 318-02 as Appendix A.

I will appreciate If somebody corrects me if i am wrong.

- Thread starter

- #9

Thanks HTURKAK attachments in post #5 were very helpful

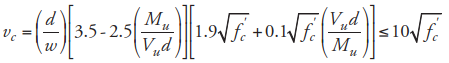

Also I looked at CRSI milkshakelake but couldn't get a reasonable capacity for one way shear with the formula shown, the factor 3.5-2.5(Mu/Vud) can be close to zero in cases which means capacity is close to zero

HTURKAK, with bursting, was looking into this a while ago and noticed end result for pilecaps was generally not to allow for bursting reinforcement

The ACI paper in post #5 mentioned confinement by plain concrete

Have you come across any other reference that elaborates on this also, reason I ask is that some do allow for bursing reinforcement

Paradoxically for a narrow column there is no plain concrete to confine, but bursting not an issue since since AS 3600 for example says it's a prsimatic compression field. But if you did add plain conrete around wouldn't the stress field diverge?

Also I looked at CRSI milkshakelake but couldn't get a reasonable capacity for one way shear with the formula shown, the factor 3.5-2.5(Mu/Vud) can be close to zero in cases which means capacity is close to zero

HTURKAK, with bursting, was looking into this a while ago and noticed end result for pilecaps was generally not to allow for bursting reinforcement

The ACI paper in post #5 mentioned confinement by plain concrete

Have you come across any other reference that elaborates on this also, reason I ask is that some do allow for bursing reinforcement

Paradoxically for a narrow column there is no plain concrete to confine, but bursting not an issue since since AS 3600 for example says it's a prsimatic compression field. But if you did add plain conrete around wouldn't the stress field diverge?

canwesteng

Structural

Is there any actual test data to show S+T is unconservative for pile caps? Of course if you just punch the formulas in ACI 318 now that they have properly accounted for size effects in deep members, a one way failure mode is going to control, but that's not a strictly correct failure mechanism and is the reason you use strut and tie for these members.

HTURKAK

Structural

- Jul 22, 2017

- 3,401

- In case of deep pile caps , ( the strut confined by plain concrete ) ,The compression stress shall be limited to avoid transverse splitting/ bursting in concrete. The strut is bottle shaped. The following figure is copy and paste from ACI 318-11HTURKAK, with bursting, was looking into this a while ago and noticed end result for pilecaps was generally not to allow for bursting reinforcement

The ACI paper in post #5 mentioned confinement by plain concrete

Have you come across any other reference that elaborates on this also, reason I ask is that some do allow for bursing reinforcement

Paradoxically for a narrow column there is no plain concrete to confine, but bursting not an issue since since AS 3600 for example says it's a prsimatic compression field. But if you did add plain conrete around wouldn't the stress field diverge?

- In case of deep beam , the strut is in rectangular form and there is transversal reinf. mesh crossing the struts.

- Thread starter

- #12

I would go a step further and suggest that a good majority of nonflexural concrete elements are still not properly designed using S&T principles (at least from what I have seen).It begs to ask the question are all the pile caps that we have designed without bursting reinforcement not fit for purpose?

Pile caps are one thing, but the same goes for joint regions in cantilever retaining walls, portal frames, bridge barriers, pedestals, etc. I have even seen corbels - the textbook example (literally) of when to use S&T - designed as if they are just short cantilevers with no regard to proper anchorage, control of cracking/bursting, etc.

For some reason, engineers baulk at the idea of having to learn S&T, and many never really see the purpose of it. It seems to be this kind of arcane field of structural engineering that you only ever see in textbooks. In my experience, most engineers I have worked with would not even be aware that S&T modelling is required in many cases to satisfy design codes.

I have long held the view that many structures around us only work because of the generous load factors slapped on top of them and that too many structural engineers are basically none-the-wiser about it. I suspect that if tested to failure, many of these structures would exhibit a lot less strength (and just as importantly, ductility) than what the designer had intended.

Similar threads

- Replies

- 3

- Views

- 8K

- Locked

- Question

- Replies

- 3

- Views

- 4K

- Question

- Replies

- 3

- Views

- 9K

- Replies

- 5

- Views

- 3K

- Replies

- 6

- Views

- 8K