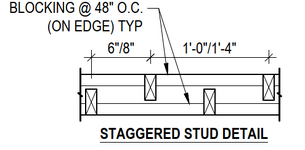

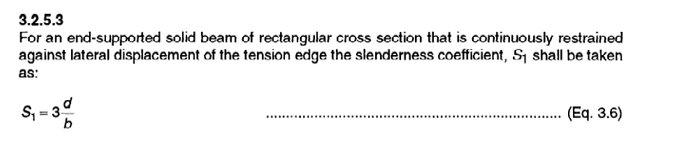

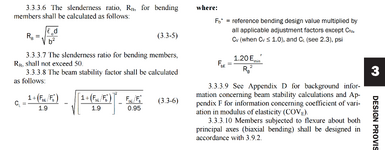

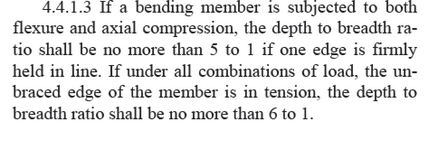

Got a customer wanting to use a staggered stud wall for thermal break purposes. It will use 2x8 plates and 2x6 @ 24" O.C. at the exterior and 2x4 @ 24" O.C. on the interior. The wall is about 11 ft. tall. has a 15 psf wind and about 500 plf axial. Have we decided that fastening one "flange" of the stud to the exterior sheathing is sufficient to brace for LTB?

I'd like to add some mid-height blocking just because or a 2x4 brace between the 2x4 and 2x6 but I am sure the customer will pushback.

I'd like to add some mid-height blocking just because or a 2x4 brace between the 2x4 and 2x6 but I am sure the customer will pushback.