medeek

Structural

- Mar 16, 2013

- 1,104

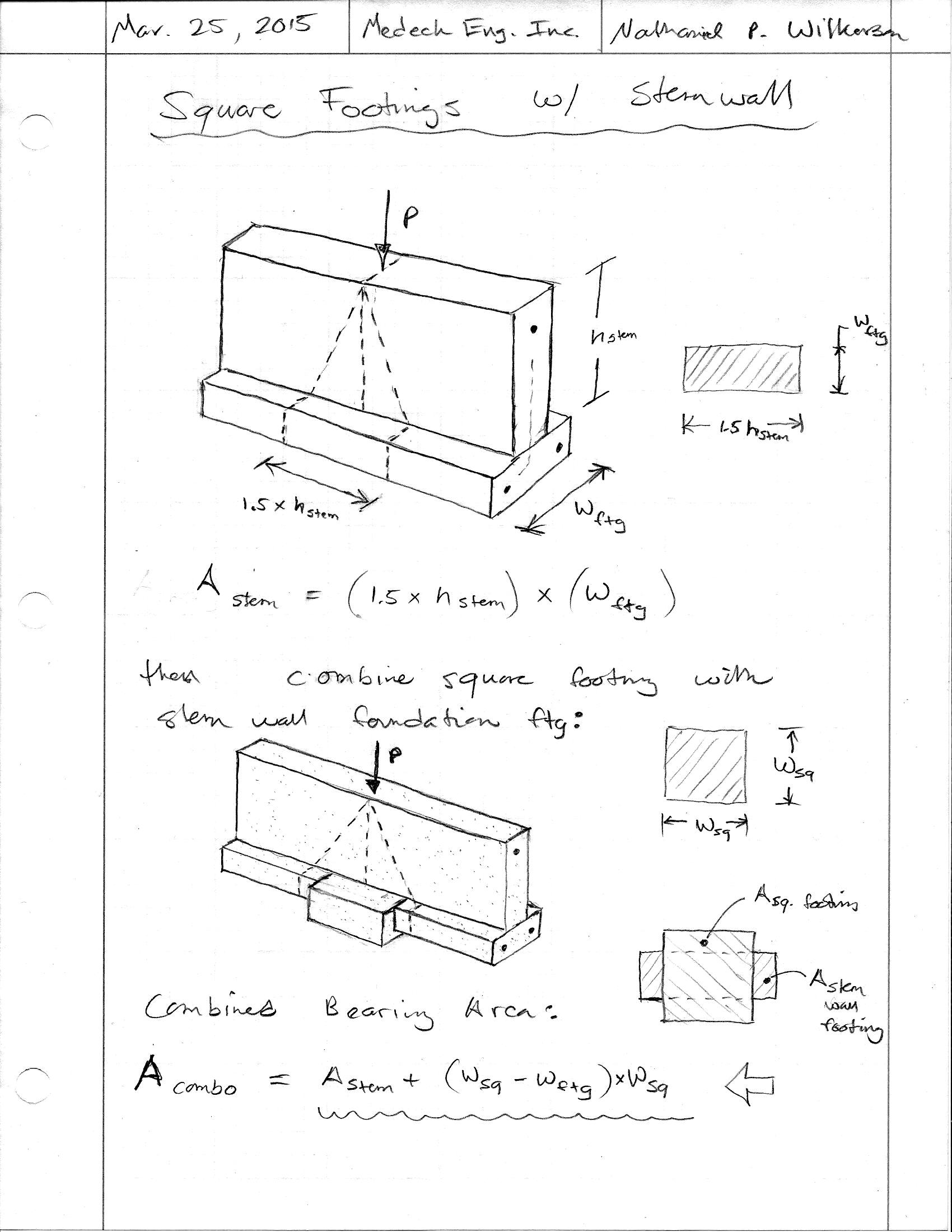

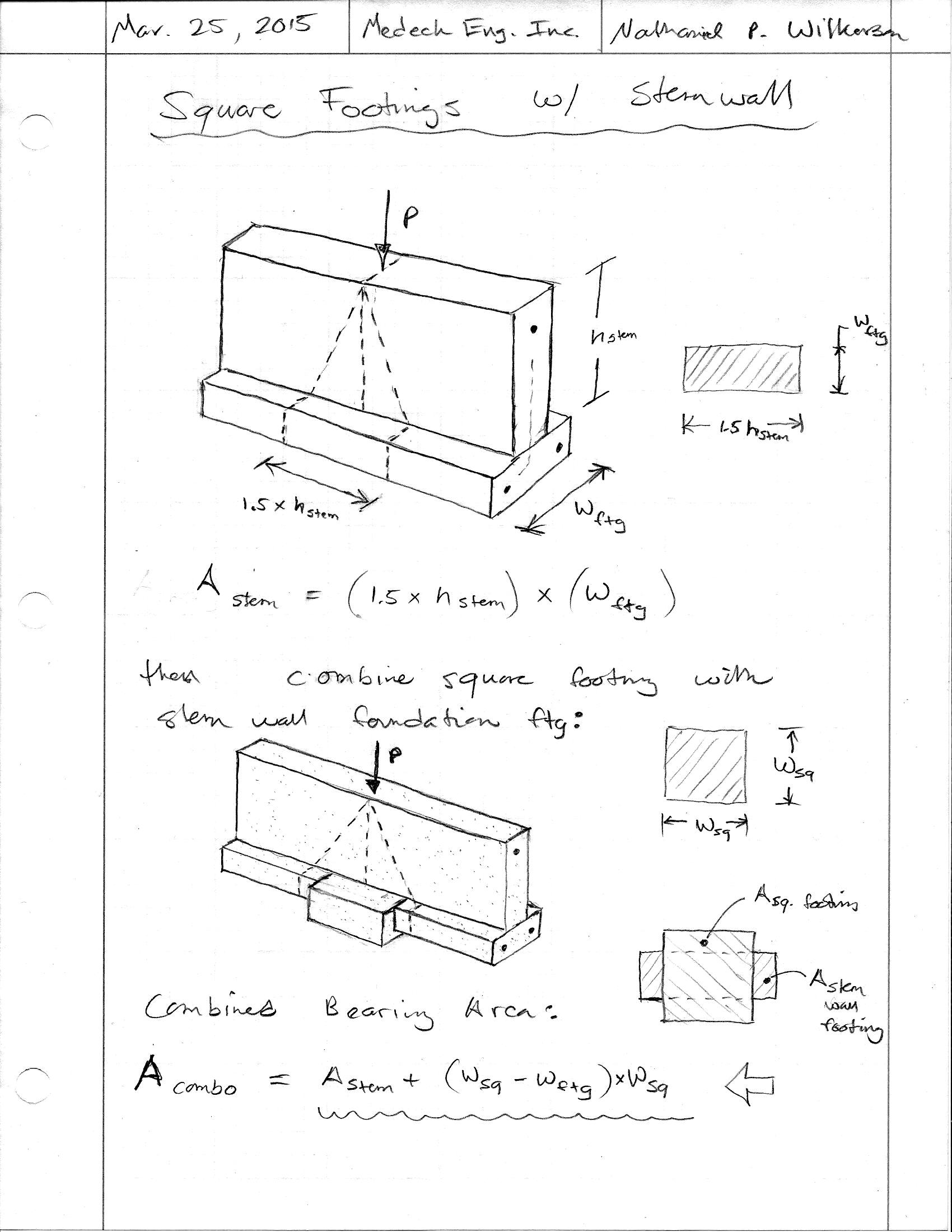

Occasionally I encounter a point load from posts that exceed the bearing capacity of a stemwall foundation footing. I then typically call out a square footing (ie. 24"x24"x12" w/ (3) #4 bars each way) to increase the bearing capacity at this location. However, in certain situations I've noticed that the number don't quite work for the stemwall footing alone or the square footing alone. It would seem logical that one could combine the bearing areas of both the continuous footing and the square footing and the total bearing area would account for this overlap as shown in the diagram below:

Does this seem like a rational and reasonable assumption to make?

Up until now I have simply ignored the contribution from the stemwall footing and sized the square footing as if it were an isolated footing.

A confused student is a good student.

Nathaniel P. Wilkerson, PE

Does this seem like a rational and reasonable assumption to make?

Up until now I have simply ignored the contribution from the stemwall footing and sized the square footing as if it were an isolated footing.

A confused student is a good student.

Nathaniel P. Wilkerson, PE