JStructsteel

Structural

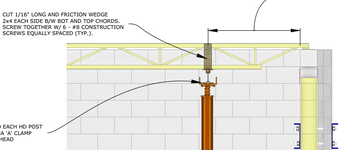

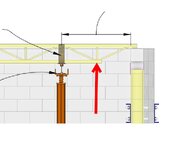

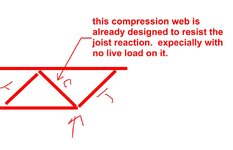

Got some steel joists with a slab on top to shore while the wall is removed and beam installed. My plan was 4x4 under the top chord about 6-8" back from the support, and that be supported by a wood wall.

I dont want to goto bottom chord due to reversal of forces.

Anyone see an issue? Perhaps a bearing pad on the wood so the chord doesnt dig into it?

I dont want to goto bottom chord due to reversal of forces.

Anyone see an issue? Perhaps a bearing pad on the wood so the chord doesnt dig into it?