Hi all,

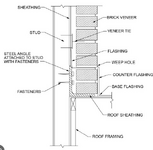

Quite frequently there have been times where brick veneer support is missed and we are having to use the existing cold form exterior studs to fasten an angle to, to pick up brick veneer.

Couple questions based on this condition is

I look forward to hearing from you,

Thank you.

Quite frequently there have been times where brick veneer support is missed and we are having to use the existing cold form exterior studs to fasten an angle to, to pick up brick veneer.

Couple questions based on this condition is

- Through bolts to go through only 1 flange or extend through both flanges?

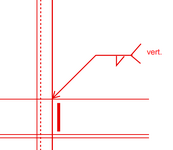

- Do you need to have 2-through bolts with a distance d between them? Or does 1 bolt in tension and the compression is taken by the bearing face of the vertical angle leg (see image below)?

- International Residential Code (IRC) R703.8.2.1 Support by steel angle specifies the use of a 4"x6"x5/16" into a double 350S162 cold-formed steel studs at max 16" o.c. with two 7/16" bolts with washer.

- What is the min. thickness for a 3.5in deep stud? is it a 350S162-33 (20 gauge)?

- Are the double 350S162 in the IRC meant to be back-to-back studs? Or boxed stud?

- Do the through bolts only go through 1 flange or extend through to both flanges?

- If it is back-to-back studs do you put 2-through bolts per stud flange i.e. 4 bolts total for a back-to-back condition? And is the orientation of the studs as shown below with a vertical distance d between the bolts?

I look forward to hearing from you,

Thank you.