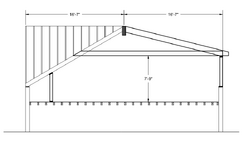

I have a client that wants to put a shed dormer on the rear of an existing 2.5 story brick house to convert the attic into living space. Dormer is to run the entire length of the building (21 feet). Plan is to cut out the rear of the roof, anchor a sill to the existing brick, install a 2x6 wall ~ 5 ft tall atop the brick, and then add the new 2x12 rafters at 3:12 slope.

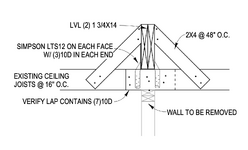

There will be a ceiling joist, but I'm not convinced it is low enough to be effective. I would prefer a structural ridge here. Drop in an LVL ridge beam; everyone sleeps at night. Client is OK with this and actually prefers a structural ridge for the same reason.

Here's the twist:

There is an existing gable dormer on the front of the house.

In my opinion, the existing valley rafters and cross ridge are structural members, i.e. the reactions need full support. That brings a point load in dead center of my proposed structural ridge.

I can get a reasonable size LVL to take the point load if the rest of the roof around it is "conventionally" framed. (Existing ridge is a rough cut timber; 100 year old house.)

If there were no point load, I can get a reasonable size LVL as a structural ridge to carry the uniform load coming from the front portion of the roof, which I now think I need to carry.

The point load on top of the uniform load kills the beam and pushes me to a very deep LVL or even steel, which is not feasible here.

Thoughts?

Has any one run into this situation?

There will be a ceiling joist, but I'm not convinced it is low enough to be effective. I would prefer a structural ridge here. Drop in an LVL ridge beam; everyone sleeps at night. Client is OK with this and actually prefers a structural ridge for the same reason.

Here's the twist:

There is an existing gable dormer on the front of the house.

In my opinion, the existing valley rafters and cross ridge are structural members, i.e. the reactions need full support. That brings a point load in dead center of my proposed structural ridge.

I can get a reasonable size LVL to take the point load if the rest of the roof around it is "conventionally" framed. (Existing ridge is a rough cut timber; 100 year old house.)

If there were no point load, I can get a reasonable size LVL as a structural ridge to carry the uniform load coming from the front portion of the roof, which I now think I need to carry.

The point load on top of the uniform load kills the beam and pushes me to a very deep LVL or even steel, which is not feasible here.

Thoughts?

Has any one run into this situation?