fairyfales

Student

- May 28, 2025

- 7

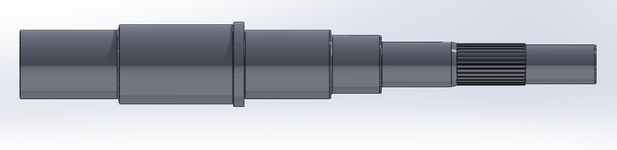

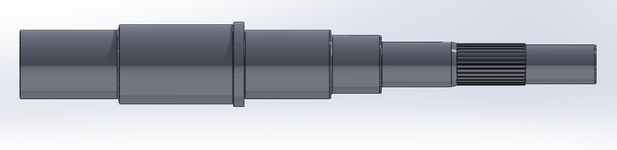

I’m working on an engineering project analyzing the cause of repeated shaft failure in a translation gear reducer that drives a support wheel of a 400-ton bucket wheel excavator.

System Details

- Shaft material: 42CrMo4

- Motor power: 5.5 kW , n=1000 t/min

- Reducer output power: 4 kW

- Gear ratio: 150:1

- Number of support wheels: 16

- Each shaft supports 1 wheel (load ≈ 25 tons)

- Bearings: 2 cylindrical roller bearings

- Support wheel diameter: 710 mm

- Translation speed: Varies between 1.5 mm/min and 15 mm/min