Looking for some insight on how to accommodate building expansion in some seismic supports for rooftop ductwork.

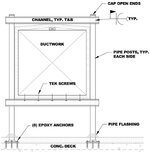

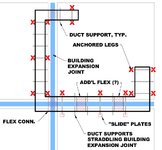

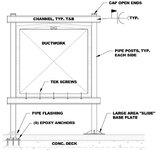

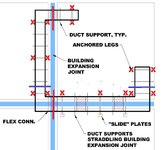

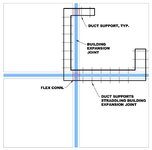

Building expansion in 1 direction is one thing, but I'm unsure how to handle 2 directions. See sketch below:

Currently thinking some canvas duct when crossing the E-W expansion could work; since the seismic stands would be fixed on each side of the N-S expansion, would some slotted holes be sufficient to account for that expansion? What if only the NE quadrant moves both N & E? (Is that even a possibility?) Would some sort of slide plate need to be designed?

(Note that relocating the duct is not a possibility)

Any assistance is greatly appreciated.

Thank you!

Building expansion in 1 direction is one thing, but I'm unsure how to handle 2 directions. See sketch below:

Currently thinking some canvas duct when crossing the E-W expansion could work; since the seismic stands would be fixed on each side of the N-S expansion, would some slotted holes be sufficient to account for that expansion? What if only the NE quadrant moves both N & E? (Is that even a possibility?) Would some sort of slide plate need to be designed?

(Note that relocating the duct is not a possibility)

Any assistance is greatly appreciated.

Thank you!