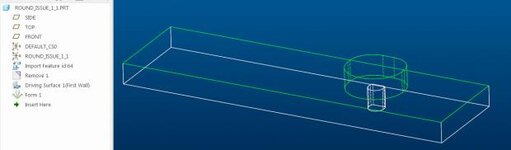

I looked at your model and it is a little hard to understand your goal. Keep in mind

Keep in mind the following points when using the Punch Form tool or the Die Form tool:

• You must assign

radii values for form and die geometry that are

greater than the value of the sheet metal thickness, otherwise the part may fail during regeneration.

• When the reference model contains a combination of concave and convex surfaces, the resulting hollows must not drop below the base plane or mating surface.

• You can create a coordinate system reference within the form to define the strike point on the part during the manufacturing process.

• You can set the dependency of the punch or die form feature on the reference model when you place it using Inheritance. You can set it to update automatically when the reference model changes, update it manually when the reference model changes, or be independent of the reference model. When you create a feature with No Dependency it does not update, and no notification appears, when there are changes to the reference model.

View attachment 6995

I advise making a very simple model to use to learn how to use this function.