MHEngineer

Structural

- Jun 15, 2025

- 3

I am having issues understanding why the concrete design codes ACI or AS3600 particularly allow shear ties to be fully developed with a cog/hook C8.2.3.4 while any other reinforcement is reduced by 50% by the hook/cog as per AS3600 chapter 13 C13.1.2.6.

AS3600 commentary states that the fitment relies on the transverse compressive pressure for anchorage, is there any reference for this?

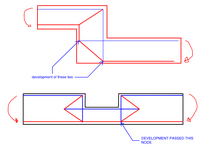

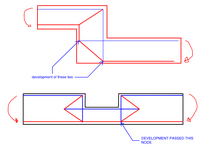

The issue stems from the problem when doing strut and tie modelling and the bar needs to develop right at the edge, could I use the same logic as tie/fitment reinforcement if I have an inclined strut at the node such as the one found in shear tie truss model

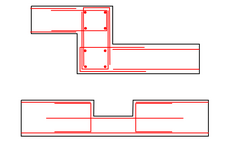

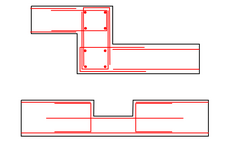

PS what I usually do is provide a U-bar where I need direct development as per below

Which I generally reinforce for as such

My two questions would be then:

1. Why does AS3600 (and I think ACI) allow a shear tie to have full development directly from the cog and hook but any other reo can only have 50% due to cog and reo and remaining needs to be developed conventionally.

2. In an STM model as the ones above, can I use a U-bar to obtain full development when the node is directedly at the edge? surely a U-bar enclosed a transverse bar is better than a hooked/cogged bar where the code allows for development for shear.

Cheers

AS3600 commentary states that the fitment relies on the transverse compressive pressure for anchorage, is there any reference for this?

The issue stems from the problem when doing strut and tie modelling and the bar needs to develop right at the edge, could I use the same logic as tie/fitment reinforcement if I have an inclined strut at the node such as the one found in shear tie truss model

PS what I usually do is provide a U-bar where I need direct development as per below

Which I generally reinforce for as such

My two questions would be then:

1. Why does AS3600 (and I think ACI) allow a shear tie to have full development directly from the cog and hook but any other reo can only have 50% due to cog and reo and remaining needs to be developed conventionally.

2. In an STM model as the ones above, can I use a U-bar to obtain full development when the node is directedly at the edge? surely a U-bar enclosed a transverse bar is better than a hooked/cogged bar where the code allows for development for shear.

Cheers