Kristofer-O

Mechanical

- Jun 20, 2025

- 5

Hi guys,

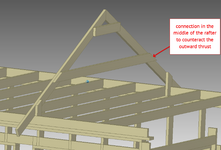

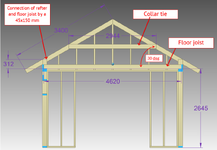

I'm building myself a garage and I wanted to get your opinion on wall thrust and the rafter and wall plate connection. All the dimensions are in mm.

As you see on the picture, I want to connect the rafter to the floor joist using a 45x145 mm material. I was wondering is there a concern that the outward thrust that the rafter exerts wants to bend that piece outward? At the moment I have the collar tie there to prevent the rafters from pushing outward but what would happen if I remove the collar tie? Would then the outward thrust bend the rafters apart?

Appreciate all thoughts

I'm building myself a garage and I wanted to get your opinion on wall thrust and the rafter and wall plate connection. All the dimensions are in mm.

As you see on the picture, I want to connect the rafter to the floor joist using a 45x145 mm material. I was wondering is there a concern that the outward thrust that the rafter exerts wants to bend that piece outward? At the moment I have the collar tie there to prevent the rafters from pushing outward but what would happen if I remove the collar tie? Would then the outward thrust bend the rafters apart?

Appreciate all thoughts