Hi all

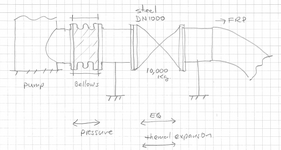

I have been presented with the piping arrangement below. Canned pump discharge, bellows, steel pipe spool with valve, FRP Piping, I need to design the supports for the pipe spool, As we all know allowable pump nozzle loads are low.

Operating case needs the supports to flex or slide a little so the bellows tie rods become engaged and there is a path for pressure tension load.

The problem is earth quake loads from the mass of the pipe spool and valve. This load will either tension the tie rods and over load the pump nozzle or slacken the rods and put a pressure load on the pump body.

I do not want to anchor the spool because thermal expansion will slacken the rods, then, as above, pump and anchor would see the pressure load.

Am I over thinking this?

Are pump bodies and anchorage designed for pressure trust loads?

Thanks in advance.

I have been presented with the piping arrangement below. Canned pump discharge, bellows, steel pipe spool with valve, FRP Piping, I need to design the supports for the pipe spool, As we all know allowable pump nozzle loads are low.

Operating case needs the supports to flex or slide a little so the bellows tie rods become engaged and there is a path for pressure tension load.

The problem is earth quake loads from the mass of the pipe spool and valve. This load will either tension the tie rods and over load the pump nozzle or slacken the rods and put a pressure load on the pump body.

I do not want to anchor the spool because thermal expansion will slacken the rods, then, as above, pump and anchor would see the pressure load.

Am I over thinking this?

Are pump bodies and anchorage designed for pressure trust loads?

Thanks in advance.