Pavan Kumar

Chemical

Hi All,

I sized a PSV downstream of a Control Valve for its wide-open failure case and got a 6"Q8" PSV. The required relief rate is 254107 lb/hr with Oxygen as the fluid. The rated capacity of the PSV is 294,851 lb/hr with 10% overpressure. I tried to size the inlet/outlet lines to this PSV. The PSV inlet line is 2 ft long and the outlet pipe is 4 ft long with an elbow. The PSV is to be installed on the 6" line downstream of the control valve with option to move it to the 12" line.

View attachment 10578

My questions:

1. The PSV Inlet pressure drop should be calculated from the source of pressure, in this case from the control valve outlet flange or can I calculate it from the reducing inlet to PSV Inlet?.

My Calculations : (i) When I used 6" inlet line taking off 6" line the inlet pressure drop is 13 psi, which is 4.8% of the PSV Set pressure. I used AFT Arrow to do these calculations. If install the PSV on the 12" line and use 8" inlet with a 8"X6" reducer at the PSV inlet I still 4.8% inlet DP. Also this calculating the pressure drop from the TEE inlet and not the Control Valve outlet flange. Is there an option that you can suggest to reduce this DP to less than 3%. I can go with a Pilot Operated PSV option whose capacity is not reduced by the inlet line pressure losses. But that is an expensive option and I want to avoid it if possible as the body and trim will be made of Monel for Oxygen service.

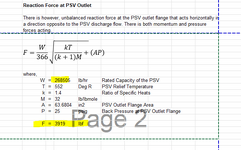

2. For the outlet side, I used a 8"X12" expander, followed by 12" Sch 10 pipe that is 4 feet long and calculated the pressure drop to be 7.2% of the PSV Set pressure. The velocity is sonic across the PSV, becomes sub-sonic in the outlet line after the 8"X12" expander and reaches sonic at the pipe exit. I want to know if this acceptable. If I use 10" pipe then the pressure drop goes to 9.5% of set pressure. My AFT Arrow model screens shot for the 12" pipe option is shown below. You can see that even though I want 0 psig at the pipe exit, the model achieves only 0.42 psig. If I use 10" pipe then it reaches 6.7 psig (result pasted as well).

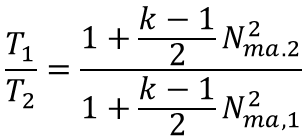

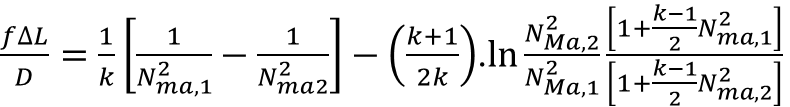

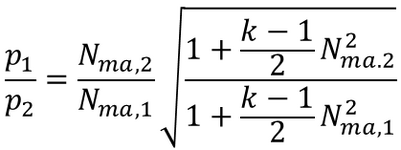

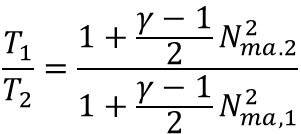

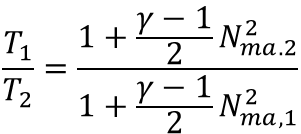

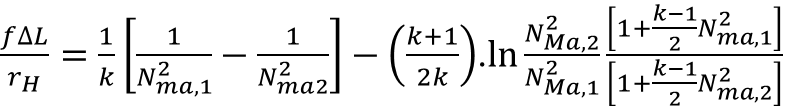

I also did calculations using my spreadsheet using isothermal compressible equation and I get 4% for the Inlet pressure drop and 22% for the outlet pressure drop. My excel calcs are close for the inlet side(4% vs. 4.8%) but there is large difference for the outlet side ( 22% vs. 7.2% ). My spreadsheet is attached also. I did this to cross-check AFT Arrow calcs. I wanted to understand why these are so different.

12" Outlet Pipe Option

10" Outlet Pipe Option:

Thanks and Regards,

Pavan Kumar

I sized a PSV downstream of a Control Valve for its wide-open failure case and got a 6"Q8" PSV. The required relief rate is 254107 lb/hr with Oxygen as the fluid. The rated capacity of the PSV is 294,851 lb/hr with 10% overpressure. I tried to size the inlet/outlet lines to this PSV. The PSV inlet line is 2 ft long and the outlet pipe is 4 ft long with an elbow. The PSV is to be installed on the 6" line downstream of the control valve with option to move it to the 12" line.

View attachment 10578

My questions:

1. The PSV Inlet pressure drop should be calculated from the source of pressure, in this case from the control valve outlet flange or can I calculate it from the reducing inlet to PSV Inlet?.

My Calculations : (i) When I used 6" inlet line taking off 6" line the inlet pressure drop is 13 psi, which is 4.8% of the PSV Set pressure. I used AFT Arrow to do these calculations. If install the PSV on the 12" line and use 8" inlet with a 8"X6" reducer at the PSV inlet I still 4.8% inlet DP. Also this calculating the pressure drop from the TEE inlet and not the Control Valve outlet flange. Is there an option that you can suggest to reduce this DP to less than 3%. I can go with a Pilot Operated PSV option whose capacity is not reduced by the inlet line pressure losses. But that is an expensive option and I want to avoid it if possible as the body and trim will be made of Monel for Oxygen service.

2. For the outlet side, I used a 8"X12" expander, followed by 12" Sch 10 pipe that is 4 feet long and calculated the pressure drop to be 7.2% of the PSV Set pressure. The velocity is sonic across the PSV, becomes sub-sonic in the outlet line after the 8"X12" expander and reaches sonic at the pipe exit. I want to know if this acceptable. If I use 10" pipe then the pressure drop goes to 9.5% of set pressure. My AFT Arrow model screens shot for the 12" pipe option is shown below. You can see that even though I want 0 psig at the pipe exit, the model achieves only 0.42 psig. If I use 10" pipe then it reaches 6.7 psig (result pasted as well).

I also did calculations using my spreadsheet using isothermal compressible equation and I get 4% for the Inlet pressure drop and 22% for the outlet pressure drop. My excel calcs are close for the inlet side(4% vs. 4.8%) but there is large difference for the outlet side ( 22% vs. 7.2% ). My spreadsheet is attached also. I did this to cross-check AFT Arrow calcs. I wanted to understand why these are so different.

12" Outlet Pipe Option

10" Outlet Pipe Option:

Thanks and Regards,

Pavan Kumar

Attachments

Last edited: