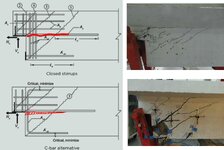

I am working on concrete repairs in the parkade of an existing building. There is a horizontal crack in one of the precast double T-beam webs staring from the steel embed shoe (see attached photos for reference). The crack is 50 mil at the largest and then tapers to nothing approximately 30” away. This cracking occurs on both sides of one of the webs in a double T-beam at the end where it is being supported on a beam ledge.

Is this an acceptable shear crack that is being controlled by the reinforcing steel or is this something more serious? I don’t have a strong knowledge of cracking in precast elements and would appreciate people’s thoughts on this. Thanks!

Is this an acceptable shear crack that is being controlled by the reinforcing steel or is this something more serious? I don’t have a strong knowledge of cracking in precast elements and would appreciate people’s thoughts on this. Thanks!