I have inherited a project where 5/16" HSS is being used for an industrial platform which will be decked in checker plate. The HSS is already purchased.

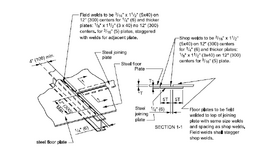

The previous designer had the floor plate field welded to HSS in overhead position. This is a hell of a lot of overhead welding, and think there should be some better solution to attach them with fasteners.

I have seen Hollo-Bolts used before, but not in this application. I believe it should be fine, but would love to get more opinions.

The previous designer had the floor plate field welded to HSS in overhead position. This is a hell of a lot of overhead welding, and think there should be some better solution to attach them with fasteners.

I have seen Hollo-Bolts used before, but not in this application. I believe it should be fine, but would love to get more opinions.