-

1

- #1

Hello everyone,

This is from ABB ACH580 firmware manual:

Can you please break it down for me in the simplest way possible.

Say for the following motor: 600 VAC, 20HP, 19.2FLA, 1770 RPM., 60Hz

In linear mode: 600/60 = 10v/Hz. So, at 10 Hz the drive will supply the motor with 100 volts and at 20 Hz, 200 volts, etc.

In Squared mode it is difficult to determine where the model starts, but let's say at 10 Hz the drive supplied 100 volts then at 20 Hz the drive will supply 20-10=2 squared = 4 x 100 volts = 400 volts.

Is that how it's suppose to work? Does it work that way from 1 volt and keeps getting squared every increment? We're going to run out of voltage pretty quick.

Clearly I'm missing the point here?

Thanks

This is from ABB ACH580 firmware manual:

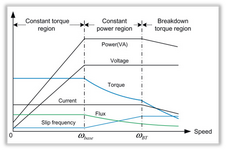

In squared mode (default), the ratio of the voltage to frequency increases as the square of the frequency below the field weakening point. This is typically used in centrifugal pump or fan applications. For these applications, the torque required follows the square relationship with frequency. Therefore, if the voltage is varied using the square relationship, the motor operates at improved efficiency and lower noise levels in these applications. Thus using squared mode saves energy.

Can you please break it down for me in the simplest way possible.

Say for the following motor: 600 VAC, 20HP, 19.2FLA, 1770 RPM., 60Hz

In linear mode: 600/60 = 10v/Hz. So, at 10 Hz the drive will supply the motor with 100 volts and at 20 Hz, 200 volts, etc.

In Squared mode it is difficult to determine where the model starts, but let's say at 10 Hz the drive supplied 100 volts then at 20 Hz the drive will supply 20-10=2 squared = 4 x 100 volts = 400 volts.

Is that how it's suppose to work? Does it work that way from 1 volt and keeps getting squared every increment? We're going to run out of voltage pretty quick.

Clearly I'm missing the point here?

Thanks