KootK

Structural

- Oct 16, 2001

- 18,670

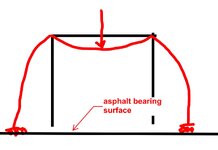

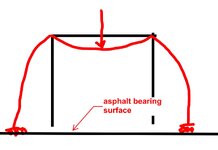

I've got a client who wants a temporary lifting frame that would bear on asphalt at the column bases.

Do I need to consider the column bases as though they are on rollers? Or am I being excessively paranoid? I'm not sure that I have a friction coefficient for this case that I trust. The bases will be sized precisely to preclude their biting into the asphalt excessively. For all I know, the base plates may land on an old oil stain.

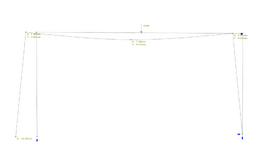

If I go ahead with this scheme, is checking the frame for the buckling mode shown below the only thing about the design that would be different from one where the base connections are laterally restrained?

Generally, is this a crazy thing to do? Would you insist on real foundations of some sort?

Do I need to consider the column bases as though they are on rollers? Or am I being excessively paranoid? I'm not sure that I have a friction coefficient for this case that I trust. The bases will be sized precisely to preclude their biting into the asphalt excessively. For all I know, the base plates may land on an old oil stain.

If I go ahead with this scheme, is checking the frame for the buckling mode shown below the only thing about the design that would be different from one where the base connections are laterally restrained?

Generally, is this a crazy thing to do? Would you insist on real foundations of some sort?