Hello,

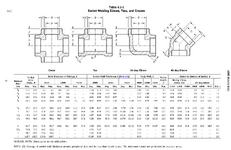

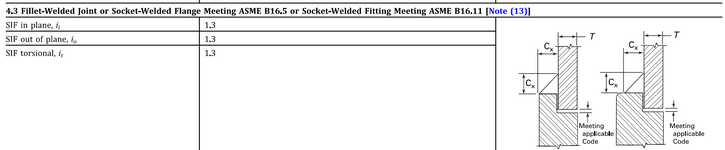

I am seeking advice on the best approach to model pipelines that incorporate ASME B16.11 fittings. These fittings appear to be quite stiff, and my concern is that I might model them as too flexible.

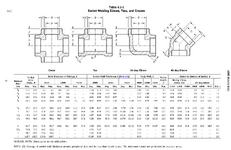

My current approach would be to simplify the model by using the minimum wall thickness specified for the body wall (G). However, since the forged parts have non-uniform wall thicknesses, with some areas being significantly thicker, I am worried this simplification could introduce inaccuracies.

What method would you recommend to accurately model these fittings while accounting for their stiffness?

Thank you for your time!

I am seeking advice on the best approach to model pipelines that incorporate ASME B16.11 fittings. These fittings appear to be quite stiff, and my concern is that I might model them as too flexible.

My current approach would be to simplify the model by using the minimum wall thickness specified for the body wall (G). However, since the forged parts have non-uniform wall thicknesses, with some areas being significantly thicker, I am worried this simplification could introduce inaccuracies.

What method would you recommend to accurately model these fittings while accounting for their stiffness?

Thank you for your time!