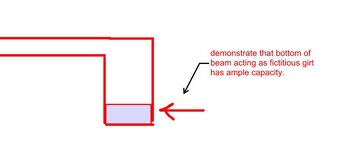

We are working on a reno where a 10kN load is being applied in the weak out of plane direction of a concrete beam. The equipment is intended to be hung from the beam with angles bolted into the concrete. I'm trying to determine whether or not the beam can resist the torsion and resolve it into the monolithic slab, or if I have to add some sort of diagonal angle bracing going up to the structural slab and check the slab for punching. Ideally I can just bolt my bracket on and move on.

Beam is 14"x26" deep, poured monolithic with a 5" slab.

I've never really dealt with concrete in torsion; I avoid it completely.

Beam is 14"x26" deep, poured monolithic with a 5" slab.

I've never really dealt with concrete in torsion; I avoid it completely.