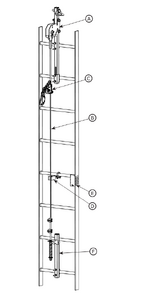

Hey all. Attached is a ladder safety system used commonly on longer length ladders. Most all manufacturer's I've spoken with rely on not exceeding the ultimate strength of the rungs, and bending is expected under these loads, reaching up to 3,600lbs (split amongst 2-3 rungs). Every manufacturer will state the supporting structure needs to be able to support the loads, so I'm assuming any ladder using these just needs to make sure the ultimate stress of the rungs is not exceeded. For steel ladders, the rungs are usually plug slot welded at the ends. Also, these systems are typically installed onto existing ladders. For new ladders, I'd just used thick enough rungs, but on existing ladders they can have 3/4" round bar rungs, and assuming it's A36 steel there isn't a ton of capacity in those.

My questions are:

1) For analysis, is it as simple as comparing the ultimate stress of the rung material to an applied stress of M/Z? or is an FEA program more useful here when exceeding the nominal moment FyZ (from AISC 15th edition section F11)?

2) For the welds at the ends, is it acceptable to use the applicable allowable strengths from Section J of AISC, or is FEA more appropriate when deformation is expected?

3) Any additional thoughts on how to put an analysis for this on paper is appreciated.

My questions are:

1) For analysis, is it as simple as comparing the ultimate stress of the rung material to an applied stress of M/Z? or is an FEA program more useful here when exceeding the nominal moment FyZ (from AISC 15th edition section F11)?

2) For the welds at the ends, is it acceptable to use the applicable allowable strengths from Section J of AISC, or is FEA more appropriate when deformation is expected?

3) Any additional thoughts on how to put an analysis for this on paper is appreciated.