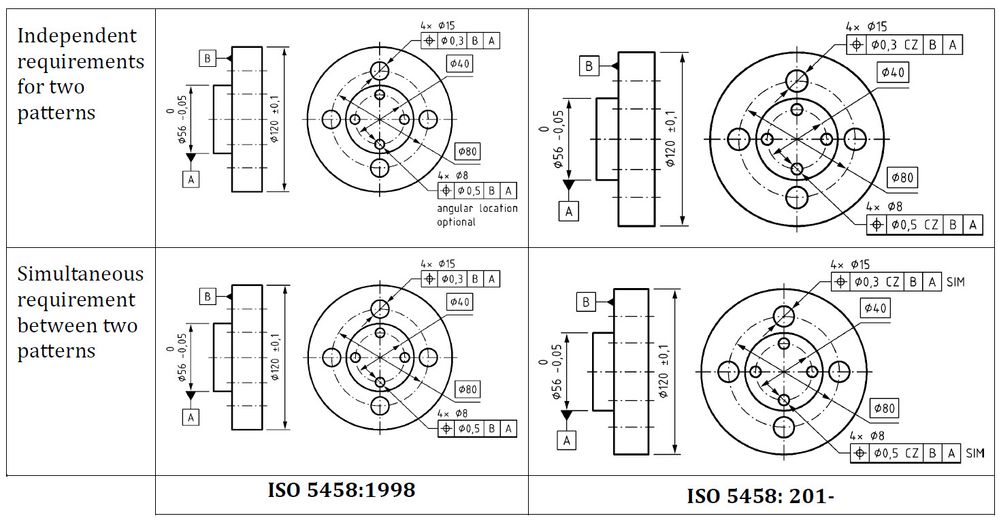

Q: Has ISO updated its simultaneous requirement definition from 1998 to 2016?

Background: One position (5 holes) has double CZ modifiers and one SIM and the second position (4 holes) has CZ and SZ and also one SIM. Same datums on both. Is simultaneous requirement implied for both sets of holes?

For my life I am not understanding those callouts.

I need some basic understanding of the simultaneous requirements in ISO. Any good discussions to point out to?

What I knew (until today) is CZ = simultaneous requirement in ISO.

Background: One position (5 holes) has double CZ modifiers and one SIM and the second position (4 holes) has CZ and SZ and also one SIM. Same datums on both. Is simultaneous requirement implied for both sets of holes?

For my life I am not understanding those callouts.

I need some basic understanding of the simultaneous requirements in ISO. Any good discussions to point out to?

What I knew (until today) is CZ = simultaneous requirement in ISO.

![[bigsmile] [bigsmile] [bigsmile]](/data/assets/smilies/bigsmile.gif)