I have designed a beam element to use as a flexure. Needs to be stainless steel for several reasons. Dimensions are 255 x 12 x 8 mm (approx 10" x 1/2" x 5/16"). They will be profile cut from 8mm plate. These are spring elements and need to operate beyond the elastic limit of the as-delivered material. We have 316 or 301 available.

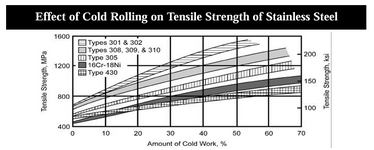

I want to increase the yield strength from the ~200 MPa (as-delivered) to at least 400 MPa. (301 in "1/2 hard" temper has a yield of 760 MPa which would be ideal)

I want to increase the yield strength from the ~200 MPa (as-delivered) to at least 400 MPa. (301 in "1/2 hard" temper has a yield of 760 MPa which would be ideal)