Hi,

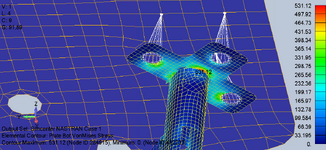

I'm seeking advice on best practices for meshing surfaces intersecting 90-degree angles using shell (plate) elements in Femap. The main challenge I'm facing is the appearance of high stresses at the sharp bends, which can lead to result uncertainties and failure in model validation checks (e.g., free-free modes, enforced motion, and thermoelastic analyses).

I've considered strategies like refining the mesh and ignoring the stress results at the corners, but I'm wondering if there are more effective approaches to handle this issue.

Any insights or suggestions you could share would be greatly appreciated!

Thanks.

I'm seeking advice on best practices for meshing surfaces intersecting 90-degree angles using shell (plate) elements in Femap. The main challenge I'm facing is the appearance of high stresses at the sharp bends, which can lead to result uncertainties and failure in model validation checks (e.g., free-free modes, enforced motion, and thermoelastic analyses).

I've considered strategies like refining the mesh and ignoring the stress results at the corners, but I'm wondering if there are more effective approaches to handle this issue.

Any insights or suggestions you could share would be greatly appreciated!

Thanks.