Brick Jagger

Structural

Hi y'all,

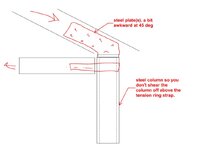

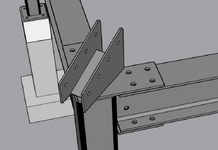

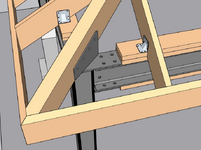

I have a 24'x24' stick frame pyramid roof with vaulted ceilings on an exterior ramada. There are no collar ties, so I plan to take the thrust out with a tension ring. I have scoured the existing threads on here about the design of this type of roof using diagonal hip beams and a tension ring at the plate. Those threads are very informative and I learned a lot, but now I'm trying to detail the hip beam to tension ring at the corners and I would like some help or direction.

The detail needs to restrain the hip beam and transfer its thrust into the tension ring All I can come up with is using screws to connect the hip to plate and a strap around the corner to tie the tension ring together. See the attached sketch. Has anyone detailed this before and can provide suggestions? Thanks!

I have a 24'x24' stick frame pyramid roof with vaulted ceilings on an exterior ramada. There are no collar ties, so I plan to take the thrust out with a tension ring. I have scoured the existing threads on here about the design of this type of roof using diagonal hip beams and a tension ring at the plate. Those threads are very informative and I learned a lot, but now I'm trying to detail the hip beam to tension ring at the corners and I would like some help or direction.

The detail needs to restrain the hip beam and transfer its thrust into the tension ring All I can come up with is using screws to connect the hip to plate and a strap around the corner to tie the tension ring together. See the attached sketch. Has anyone detailed this before and can provide suggestions? Thanks!